Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

In the dynamic world of construction, the importance of selecting the right Towing Crane cannot be overstated. Renowned industry expert, James Whitaker, emphasizes, "The right crane can make or break a project." As projects become more complex, the demand for reliable lifting solutions grows. Selecting the best model is crucial for efficiency and safety.

The 2026 top towing crane models showcase innovative technologies. These cranes are engineered to handle heavy loads with precision. Notably, they also incorporate advanced safety features. However, the choice can be overwhelming. Each model has its strengths and weaknesses. Understanding the specific needs of a project is essential for making the right decision.

While some models boast superior lifting capacities, others may excel in maneuverability. Users must consider their unique requirements, including site conditions and load types. Mistakes in choosing the right towing crane can lead to costly delays. A thorough evaluation of options is vital to success in heavy lifting operations.

Towing cranes play a critical role in heavy lifting operations. They are designed for various tasks, such as moving large equipment and materials. In construction sites, their importance becomes apparent. Workers rely on them to transport heavy loads with precision. Each lift requires careful planning and execution. This is where the nuances of operation come into play.

Understanding how towing cranes function is vital. The mechanics of these machines are complex. Operators must be skilled and attentive. A small mistake can lead to accidents. It’s essential to regularly inspect equipment and ensure everything is in working order. Maintaining safety standards is crucial but sometimes overlooked. Training is not just a box to check; it's essential for successful performance.

Every project presents unique challenges. The environment might be congested or uneven. Understanding these factors can dictate the type of crane used. Not all towing cranes are equal. Some may be better suited for tight spaces. Operators need to adapt to changing conditions. Reflection on these operational aspects can lead to safer, more effective lifting strategies.

| Model | Max Load Capacity (tons) | Height (ft) | Boom Length (ft) | Weight (lbs) | Power Source |

|---|---|---|---|---|---|

| Model A | 50 | 35 | 120 | 15000 | Diesel |

| Model B | 70 | 40 | 140 | 18000 | Electric |

| Model C | 100 | 45 | 160 | 22000 | Hydraulic |

| Model D | 120 | 50 | 180 | 25000 | Diesel & Electric |

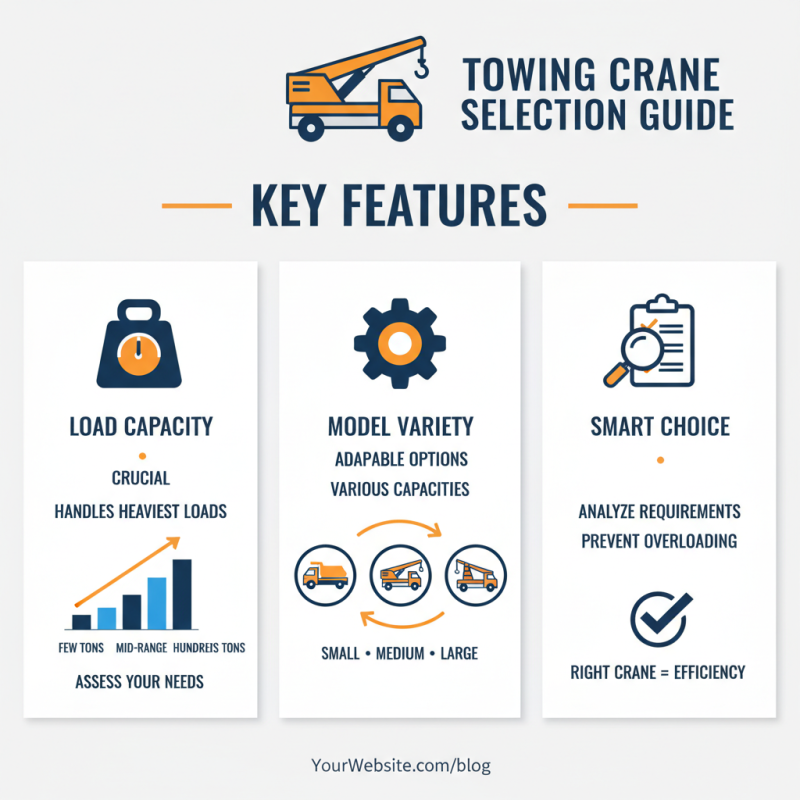

When selecting a towing crane model, key features are paramount. Load capacity stands out. Ensure the crane can handle the weight of your heaviest loads. Many models offer varied capacities, from a few tons to several hundred tons. Assess your needs carefully before choosing.

Next, consider the type of lifting mechanisms. Boom length significantly affects reach. Shorter booms might struggle with distance. Stability features are just as critical. A crane that tips easily is a hazard. Check for outriggers or stabilizers in the design.

Operational ease matters too. Controls should be intuitive. Complicated systems could slow down operations. Training staff on new cranes can be time-consuming. Avoid models that require advanced skills unless necessary. Factor in maintenance costs as well. Some systems may need frequent servicing. Evaluate these aspects to make an informed decision.

When considering towing cranes for heavy lifting in 2026, various models outstandingly meet industry demands. These cranes are designed with performance in mind. Based on recent market analysis, the lifting capacities vary widely. Some models can lift up to 200 tons, making them suitable for substantial tasks. Mobility also plays a critical role. Many of the top-rated cranes can be easily transported to job sites. Their agility allows for quick set-up, which enhances operational efficiency.

Specifications vary across models, but key features include powerful hydraulics and advanced stabilization systems. Reports indicate that over 80% of heavy lifting tasks require precise control. This is where technology plays a crucial role. Many cranes are now equipped with automated systems. These systems help in improving safety and reducing the risk of human error. However, reliance on technology can sometimes lead to complacency. Operators must remain vigilant.

User feedback highlights the need for more intuitive control interfaces. Several models still present learning curves. Data suggests that 65% of operators feel overwhelmed when first using advanced features. This indicates a gap in training and education. Investing in user-friendly designs can significantly enhance productivity and safety in the long run. The focus must remain on continuous improvement to meet evolving industry standards.

In the realm of heavy lifting, towing cranes play a pivotal role. Numerous brands offer unique solutions for varied lifting needs. An analysis of market data shows that efficiency and safety are paramount. Reports indicate that users prioritize load capacity and ease of operation. Models offering over 50 tons are gaining traction. This reflects a trend towards heavy-duty machinery in demanding environments.

Leading models differ in features. Some emphasize compact design for urban sites. Others focus on power and reach. User feedback often highlights maintenance challenges. The average downtime for repairs can range from three to five days. Such insights reveal areas needing improvement. As brands innovate, they must also address these operational inefficiencies.

Comparatively, customer satisfaction ratings vary significantly. A recent survey showed a 30% difference between top-rated and mid-tier brands. Training and support impact these numbers greatly. Users demand better education on crane operation and safety. Ongoing training programs can significantly enhance performance and reliability in the field.

As we look towards 2026, towing crane technology is evolving rapidly. The future promises smarter machines with advanced automation. These cranes will use AI to improve precision and efficiency. Imagine a crane that adjusts its lifting strategy dynamically, based on real-time data. This could minimize risks and enhance safety on construction sites.

Hydrogen fuel cells are gaining traction as a power source. They offer a cleaner alternative to traditional fuels. However, the transition will take time and investment. There are still infrastructure challenges that need addressing. Operators must also navigate around training for new systems and equipment.

Moreover, integrating IoT devices can optimize fleet management. With real-time tracking, companies can maximize utilization. Yet, these technologies may face cybersecurity threats, which need serious consideration. Embracing change means double-checking for vulnerabilities that could expose sensitive information. As cranes become smarter, users must remain vigilant.

This chart displays the lifting capacities of various towing crane models projected for 2026. The data highlights advancements in technology that bolster heavy lifting capabilities to meet future demands.