Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

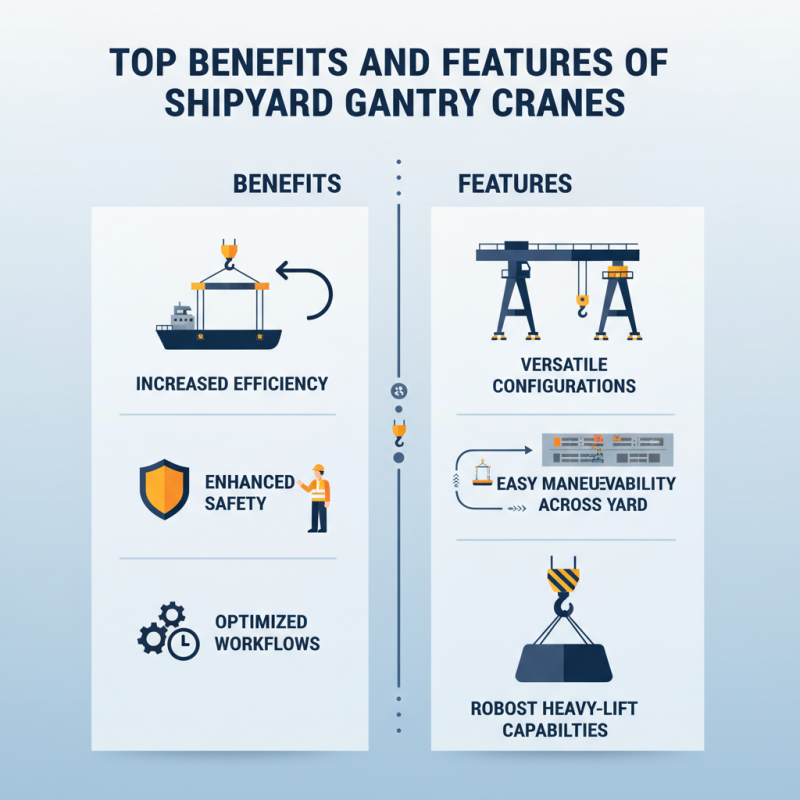

When it comes to the heavy lifting needs in shipyards, the Shipyard Gantry Crane stands out as an essential piece of equipment. Designed to improve efficiency and safety in the complex environment of shipbuilding and repair, these cranes offer a range of benefits that significantly enhance operational workflows. Their robust structure allows them to handle large and heavy components, making them indispensable in the construction and maintenance of maritime vessels.

Furthermore, the versatility of the Shipyard Gantry Crane is a notable feature that contributes to its popularity among shipyard operators. These cranes can be configured to accommodate various lifting needs, whether for moving large ship sections or managing components requiring precise placement. The ability to maneuver easily across the yard further amplifies their effectiveness, allowing for seamless logistics and work processes. This introductory exploration will delve into the top benefits and features of Shipyard Gantry Cranes that every industry professional should be aware of, highlighting how these cranes can optimize performance and enhance safety in shipyard environments.

Shipyard gantry cranes play a crucial role in maritime operations, providing significant advantages that enhance efficiency and safety in shipbuilding and maintenance. One of the key benefits of these cranes is their ability to move heavy loads with precision and ease. This capability allows shipyard workers to transport large components, such as hull sections and heavy machinery, seamlessly across the worksite, thereby reducing manual labor and minimizing the risk of accidents. Furthermore, the design of gantry cranes permits them to operate in tight spaces, making them ideal for the confined areas often found in shipyards.

Another major advantage of using shipyard gantry cranes is their versatility. These cranes can be equipped with various attachments, such as hooks, slings, and spreader bars, which makes them suitable for a wide range of lifting tasks. This adaptability is particularly beneficial in a dynamic environment like a shipyard, where the requirements may shift frequently. Additionally, their robust construction ensures they can withstand harsh marine conditions, delivering reliable performance over time. The integration of advanced technology, such as remote control and automated systems, further enhances operational efficiency, enabling crews to achieve higher productivity while maintaining safety standards.

| Feature | Description | Advantages |

|---|---|---|

| High Lifting Capacity | Designed to lift heavy loads, typically ranging from 20 tons to over 500 tons. | Enables efficient movement of large vessels and components, reducing overall handling time. |

| Mobility | Can move across various tracks within the shipyard. | Allows for flexibility in operations and the ability to service multiple locations. |

| Robust Construction | Built to withstand harsh marine environments and heavy usage. | Increases the lifespan of the equipment and reduces maintenance costs. |

| Safety Features | Equipped with limit switches, overload sensors, and emergency stop buttons. | Enhances worker safety and minimizes the risk of accidents during operations. |

| Versatile Applications | Suitable for numerous tasks including loading/unloading ships and assembling structures. | Increases operational efficiency by accommodating various maritime tasks with one machine. |

| Easy Operation | Can be operated from a control cabin or remotely using wireless controls. | Improves precision and reduces operator fatigue, leading to better performance. |

Shipyard gantry cranes play a pivotal role in enhancing operational efficiency within marine environments, and understanding their essential features can significantly impact performance. One of the critical attributes is their load capacity. According to the Industrial Crane Association, modern gantry cranes are engineered to handle loads ranging from 10 tons to over 1,000 tons, making them ideal for heavy lifting operations in shipyards. This flexibility allows facilities to accommodate various projects, from small crafts to large ships, ensuring they meet diverse operational demands.

Another essential feature is the crane’s mobility. Many shipyard gantry cranes are designed to move along rails, with some models incorporating rubber-tired gantry systems that offer increased versatility. A report by the International Maritime Organization highlights that the use of mobile cranes can reduce loading and unloading times by as much as 30%, which translates to significant time and cost savings. Furthermore, advancements in automation technology are enhancing these cranes’ performance. Equipped with intelligent control systems and remote operation capabilities, they can perform tasks with higher precision and safety, leading to minimized risks of accidents and injuries on site.

Incorporating these features into shipyard gantry cranes not only improves their functionality but also aligns with the industry's push towards safety and efficiency. As the maritime sector continues to evolve, understanding these essential features will empower operators to optimize their operations, ultimately contributing to better output and profitability.

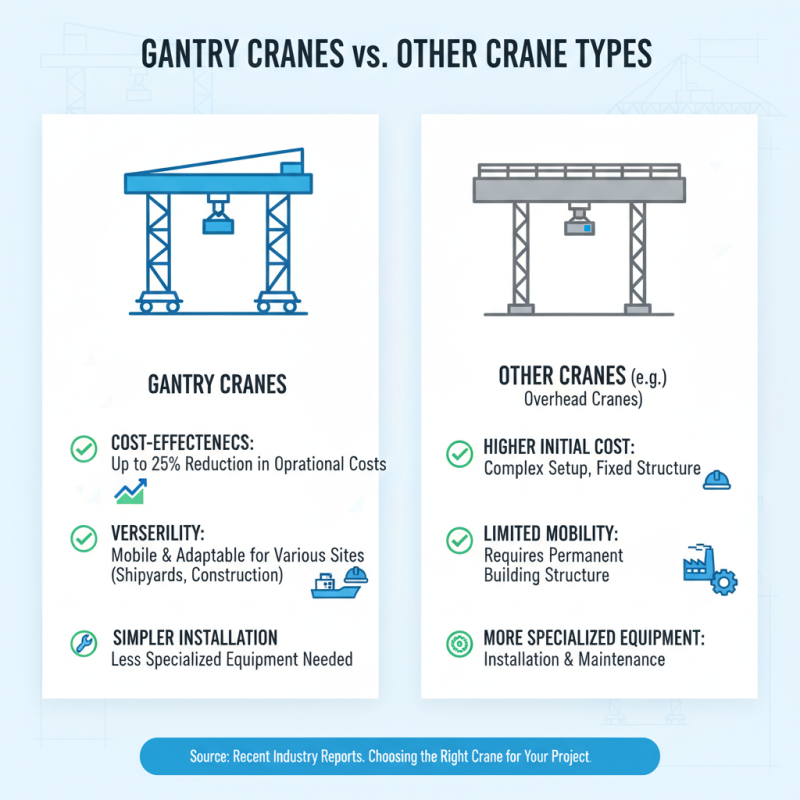

When assessing the benefits and features of gantry cranes compared to other crane types, several key distinctions emerge. Gantry cranes, known for their robust design and mobility, often outperform conventional overhead cranes in terms of cost-effectiveness and versatility. According to recent industry reports, gantry cranes can reduce operational costs by up to 25% due to their simpler installation and the reduced need for specialized lifting equipment. This makes them particularly attractive for shipyards and construction sites where budget constraints are paramount.

In contrast to telehandlers and tower cranes, gantry cranes provide a lower installation footprint and a greater lifting capacity on uneven surfaces like those found in shipyards. Research indicates that many businesses experience efficiency gains of around 30% when switching to gantry cranes for their material handling needs. Moreover, they can be adapted for various purposes, offering adjustable heights and spans, which is a significant advantage in dynamic working environments.

**Tips:** When selecting a gantry crane, consider the specific lifting needs of your operation, such as weight capacity and height requirements. Additionally, regular maintenance is crucial; conducting inspections can prolong the crane's lifespan and optimize its performance. Evaluate whether purchasing or renting suits your operational strategy to maximize both utility and cost savings.

The safety of workers is paramount in shipyard operations, and advancements in gantry crane technology have significantly enhanced protection measures. Modern shipyard gantry cranes are equipped with a variety of safety innovations designed to minimize risks associated with heavy lifting and operation. One prominent feature includes advanced control systems that facilitate precise movements, drastically reducing the chances of accidents caused by human error. These systems often come with overload protection mechanisms, ensuring that cranes do not lift beyond their rated capacity, which is crucial in preventing structural failures and injuries.

Additionally, many gantry cranes now incorporate enhanced visibility features such as 360-degree cameras and obstacle detection sensors. These innovations allow operators to maintain a clear view of the work environment, reducing blind spots and facilitating safer maneuvers. Furthermore, ergonomic designs in operator cabins reduce physical strain, and the integration of automated features can minimize the need for manual intervention, lowering the risk of accidents. Together, these safety innovations reflect a commitment to creating a safer working environment for employees in the demanding shipyard setting.

This chart illustrates the top benefits and features of shipyard gantry cranes, highlighting their scores in various aspects such as safety features, operational efficiency, load capacity, versatility, and ease of maintenance. These scores demonstrate the importance of innovative technology in protecting workers and enhancing efficiency in shipyards.

Proper maintenance is critical for maximizing the lifespan and performance of shipyard gantry cranes. Regular inspections should be scheduled to identify early signs of wear and tear. Key components such as hoists, wheels, and supports should be checked frequently for any damage or corrosion. Implementing a predictive maintenance strategy can be beneficial, utilizing advanced monitoring systems to track the health of the crane and predict potential failures before they occur.

Lubrication plays a significant role in maintaining the crane's functionality. Regularly applying the appropriate lubricants to moving parts can reduce friction and wear, extending the working life of these components. Additionally, keeping the gantry crane clean and free from debris not only enhances safety but also allows for easier identification of any issues that may arise. Training personnel on proper operating procedures and maintenance routines further contributes to the longevity and efficiency of the crane within the shipyard environment.