Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

In the fast-paced world of modern construction, efficiency is crucial. One tool has become increasingly popular: the Semigantry Crane. This versatile machinery combines aspects of both gantry and overhead cranes. It supports heavy loads while allowing for flexibility on job sites. Using a Semigantry Crane can streamline operations, ultimately saving time and money.

These cranes offer unique advantages that cater to various construction needs. For instance, they provide excellent height clearance and support large structures effectively. Their design allows for easy maneuvering, making them ideal for tight spaces. However, the investment in a Semigantry Crane requires careful consideration. The initial costs might seem high, and maintenance can be demanding if not properly managed. This leads to questions about project budgets and long-term benefits.

As construction projects grow more complex, the Semigantry Crane stands out. Its adaptability makes it a popular choice among contractors. Yet, it demands skilled operators and regular upkeep to maximize efficiency. The balance between performance and cost is essential. Embracing the Semigantry Crane requires reflection on its role in future projects.

Semigantry cranes offer significant advantages in modern construction projects. They enhance efficiency by enabling quick material handling. With a design that balances elevated lifting capabilities and ground-level maneuverability, these cranes transform workforce dynamics. Workers can complete tasks faster, minimizing downtime and increasing productivity. The adjustable height allows for precise work in varied construction settings, accommodating different building specifications.

Cost-effectiveness is another compelling aspect. Employing semigantry cranes reduces reliance on multiple pieces of equipment. This results in less maintenance and lower operational costs. However, the initial setup can be complex. Some teams might struggle with the required training for safe operation. It's essential to ensure that all workers are adequately trained, as improper usage may lead to accidents or equipment damage.

Flexibility in design also plays a critical role. Semigantry cranes can be tailored to project needs, making them suitable for various tasks. Nonetheless, this versatility can sometimes lead to oversights, such as underestimating load capacities. It's crucial to conduct thorough assessments to prevent mishaps. Striking the right balance between innovation and safety is key to maximizing these cranes' benefits in construction efficiency.

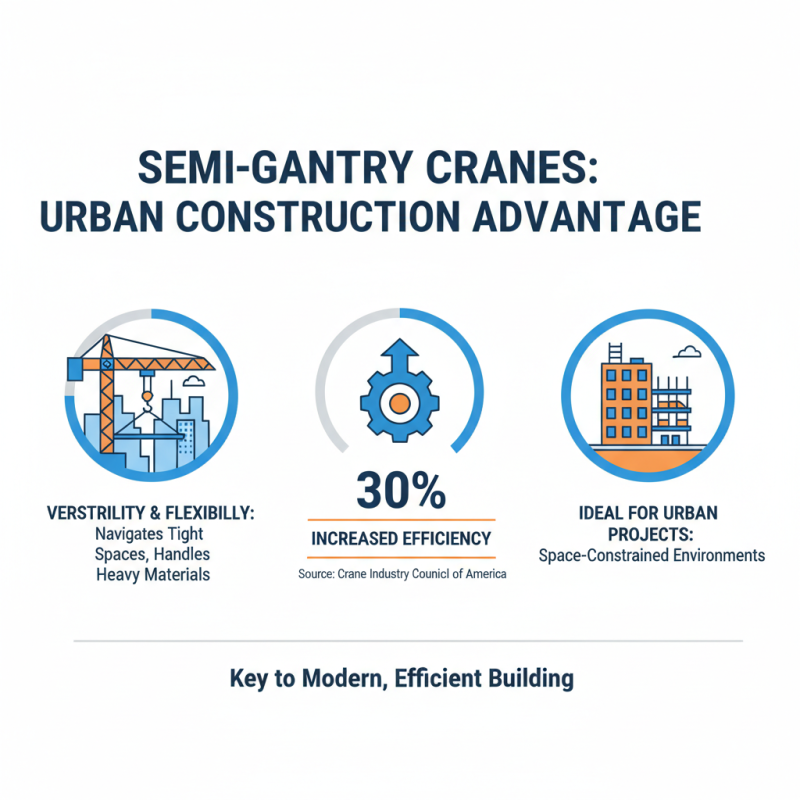

The semi-gantry crane brings remarkable versatility and flexibility to modern construction projects. These cranes can navigate tight spaces easily while handling heavy materials. According to a report from the Crane Industry Council of America, semi-gantry cranes can increase efficiency by up to 30%. This is vital in urban construction, where space is often limited.

Operators appreciate the adaptability of these cranes. They can be adjusted to meet specific project needs. For instance, when dealing with varying load heights, semi-gantry cranes provide an effective solution without compromising safety. While some users may encounter challenges with crane positioning, the benefits often outweigh the drawbacks.

Tip: To maximize gains from using a semi-gantry crane, assess your job site requirements carefully. Ensure clear communication among team members about the crane’s capabilities. Flexibility in planning can make a significant difference. Also, remember that regular maintenance can prevent many operational headaches. Keeping a close eye on wear and tear will enhance the crane's lifespan and performance.

In modern construction, semigantry cranes have emerged as cost-effective alternatives to traditional crane systems. These cranes provide significant savings during project execution. According to a report by the American Society of Civil Engineers, semigantry cranes can reduce overall project costs by up to 25%. This is largely due to lower operational costs and minimized setup times.

Moreover, semigantry cranes require less space and fewer resources, making them ideal for urban sites. With their ability to operate in tighter areas, they can enhance workflow efficiency. Industry data reveals that projects utilizing semigantry cranes report a 30% increase in project speed. However, the initial investment might seem steep compared to standard cranes. Contractors must evaluate long-term benefits over upfront expenditures. An additional consideration is the training needed for operators; they might be less familiar with this equipment.

While these cranes deliver multiple advantages, their flexibility can occasionally introduce challenges. Ensuring stable ground conditions is crucial for optimal performance. Construction teams must remain vigilant about potential site-specific issues. Emphasizing thorough site assessments could mitigate costly mistakes that arise from inadequate planning.

| Benefit | Description | Cost Savings (%) |

|---|---|---|

| Increased Flexibility | Adaptable to various projects and site layouts. | 15% |

| Reduced Labor Costs | Less manpower required for operation compared to traditional cranes. | 20% |

| Improved Safety | Designed with safety features that reduce accidents. | 10% |

| Higher Efficiency | Speeds up the lifting and moving processes. | 25% |

| Lower Maintenance Costs | Less mechanical wear compared to traditional cranes, leading to savings. | 15% |

| Space Efficiency | Requires less ground space for operation. | 5% |

| Versatile Applications | Can be used in various construction scenarios. | 10% |

| Enhanced Load Capacity | Capable of handling heavier loads with stability. | 30% |

| Reduced Setup Time | Quick to assemble and disassemble, minimizing downtime. | 20% |

| Environmental Considerations | Lower emissions and noise pollution compared to older models. | 10% |

The emergence of semigantry cranes has brought remarkable advancements in safety features for construction sites. According to a report published by the Occupational Safety and Health Administration (OSHA), nearly 20% of construction site accidents relate to equipment failures. Semigantry cranes reduce such risks through enhanced structural designs. They often have multiple safety features, including overload sensors and emergency stop mechanisms. This proactive approach significantly lowers the chances of accidents.

The ability of semigantry cranes to operate in tight spaces also contributes to increasing safety. These cranes provide optimal lifting capabilities with a compact footprint. A study by the National Institute for Occupational Safety and Health (NIOSH) shows that cranes operating in confined areas can mitigate risks by up to 30%. However, the need for proper training remains critical. Even with advanced safety technology, improperly trained operators can still lead to mishaps.

Developers also benefit from real-time monitoring systems integrated into semigantry cranes. These systems offer insights into both equipment health and site conditions. Technical reports highlight that efficient monitoring can prevent 50% of mechanical failures when used correctly. While these advancements are impressive, reliance on technology alone is not enough. Human error and decision-making still play a significant role in ensuring safety at job sites.

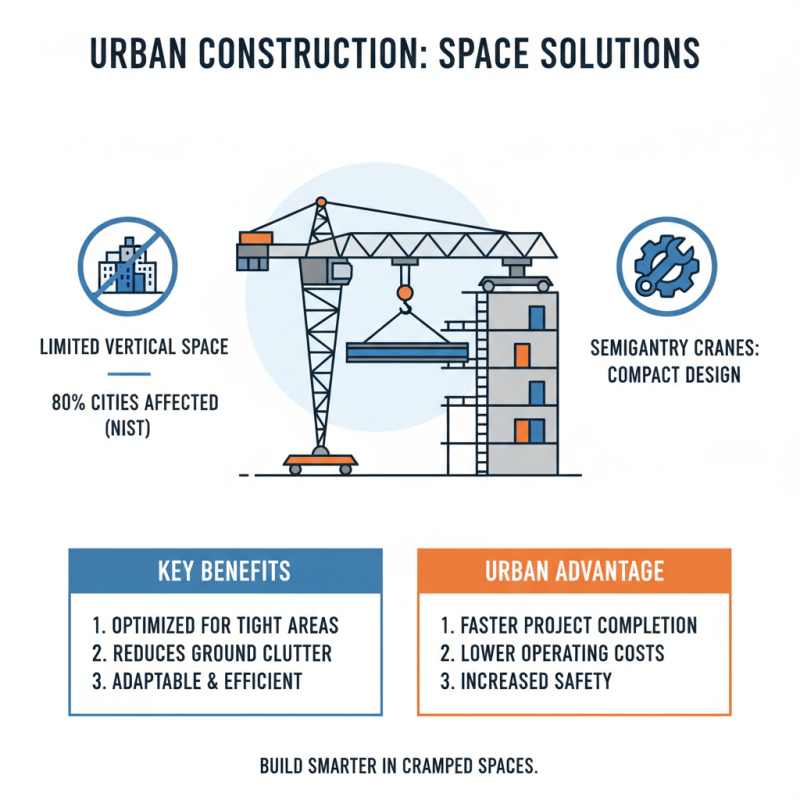

Urban construction projects often face space constraints. Semigantry cranes provide a solution. Their design allows them to operate effectively in tight areas. A report from the National Institute of Standards and Technology shows that 80% of cities report limited vertical space. This makes semigantry cranes essential for modern construction.

These cranes can be set up closer to buildings. They need less room than traditional cranes. According to the Construction Industry Institute, using semigantry cranes can save up to 30% more site space. This is crucial for urban areas where every square foot counts. More compact equipment leads to enhanced safety on crowded job sites.

Operators often face challenges with maneuverability. However, semigantry cranes mitigate many of these issues. They can adjust their height and extend their reach easily. While the cost of investment in such cranes might seem high, their efficiency often pays off. Construction timelines can be reduced significantly. This aspect is vital as urban projects tend to experience delays, leading to increased costs. The need for suitable solutions in densely populated areas is clear.