Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

In the ever-evolving landscape of construction, the choice of equipment significantly impacts a project's efficiency, safety, and overall success. An increasingly popular option among construction professionals is the underslung crane, a versatile piece of machinery that offers numerous advantages for various construction tasks. Designed to be mounted beneath a supporting structure, the underslung crane provides unique benefits that enhance both workflow and operational flexibility on job sites.

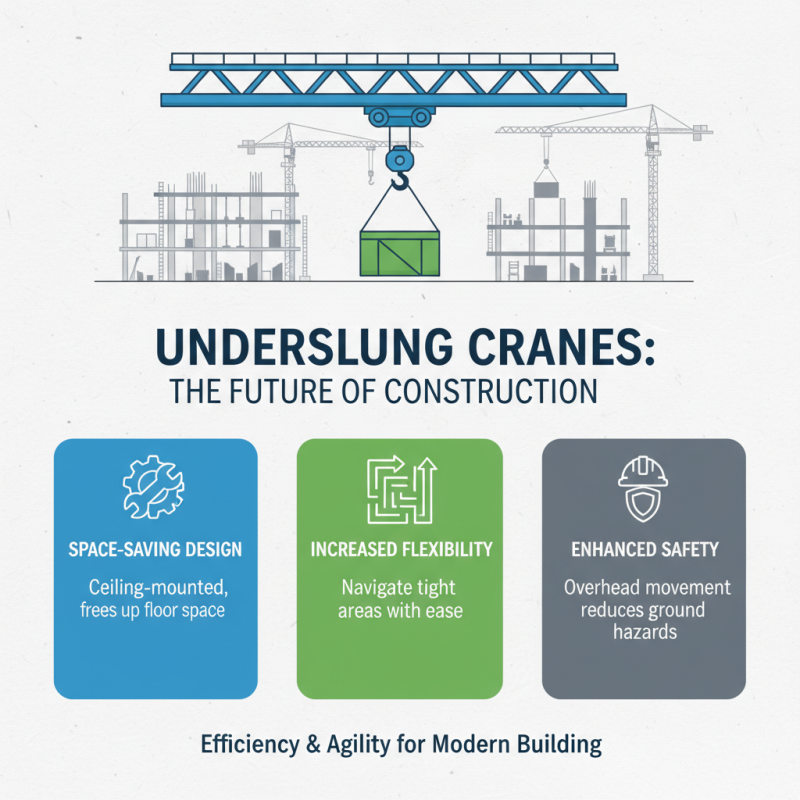

One of the primary advantages of using an underslung crane is its ability to maximize space utilization. By being suspended from a building or other support framework, it frees up valuable ground space, allowing for optimal organization of materials and personnel. This increased space not only improves safety but also enhances the speed of operations. Furthermore, underslung cranes are known for their maneuverability, enabling workers to position loads precisely where they are needed, thereby reducing downtime and boosting productivity.

In addition to practicality, underslung cranes extend the range of lifting capabilities without compromising safety. Their design allows for heavy loads to be moved efficiently, minimizing the risk of accidents associated with lifting operations. As the construction industry continues to seek solutions that combine efficiency with safety, exploring the benefits of the underslung crane can lead to improved project outcomes and a more streamlined construction process.

Underslung cranes are becoming increasingly popular in construction settings due to their unique design and numerous advantages. These cranes are suspended from the ceiling, offering several benefits that enhance operational efficiency and safety. One major advantage is their flexibility in navigating tight spaces. Unlike traditional cranes that occupy ground space, underslung cranes provide higher clearance, which allows for easy movement of materials overhead without hindering other construction activities.

In addition to space-saving capabilities, underslung cranes improve safety on job sites. By keeping the workspace clear, they reduce the risk of accidents related to ground obstacles. Moreover, their low profile helps in maintaining an unobstructed view of the work area for operators, further minimizing hazards. For projects that require lifting heavy materials, the stability and precision of underslung cranes ensure that loads are managed effectively, contributing to smoother project execution.

**Tips for optimizing the use of underslung cranes:**

1. Ensure regular maintenance checks to keep the crane in optimal condition and prevent operational downtime.

2. Train all personnel involved in the operation to enhance safety protocols and ensure effective communication on site.

3. Utilize proper rigging techniques and equipment to maximize the crane’s lifting capacity while minimizing risks.

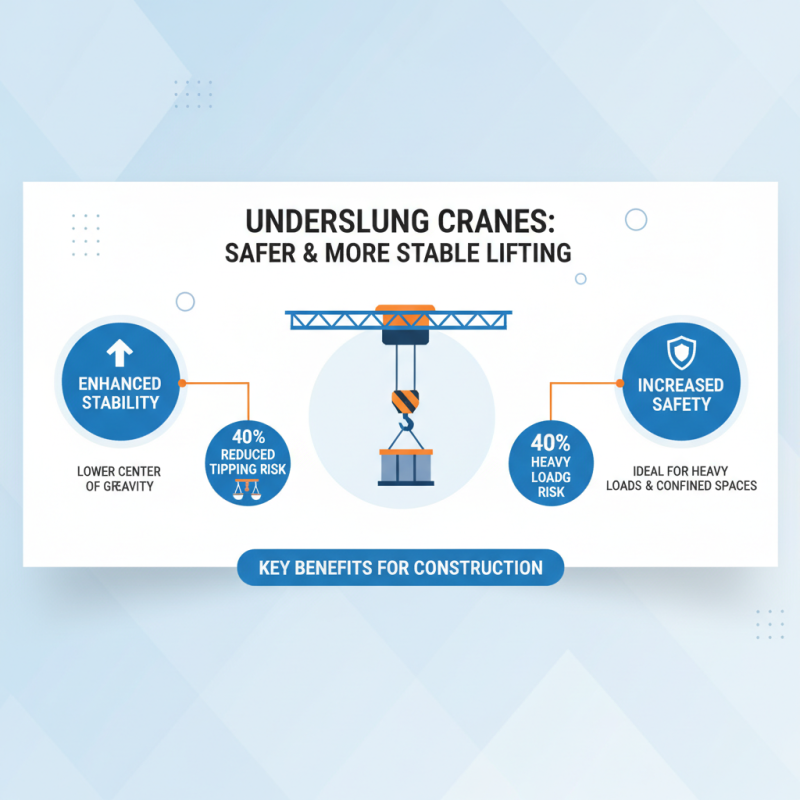

Underslung cranes have gained popularity in the construction industry due to their enhanced stability and safety features. With their unique design, which allows the crane to be suspended beneath a framework, these cranes significantly lower the center of gravity during operations. According to a report by the International Federation of Robotics, cranes with a lower center of gravity can reduce the risk of tipping over by up to 40%. This increased stability is crucial for projects that involve heavy lifting or are conducted in confined spaces.

Additionally, underslung cranes are equipped with advanced safety systems, including overload protection and real-time monitoring capabilities. A study published in the Journal of Construction Engineering and Management revealed that construction sites utilizing cranes with integrated safety features saw a 25% reduction in accidents related to lifting operations. This not only protects the workforce but also minimizes project delays stemming from accidents.

Tip: When selecting an underslung crane, ensure to evaluate its load capacity and safety mechanisms thoroughly to maximize both efficiency and safety on your site. It's essential to invest in regular maintenance checks for these cranes to maintain optimal performance. By prioritizing stability and safety, construction managers can significantly enhance the overall productivity of their projects.

Underslung cranes have gained popularity in the construction industry due to their innovative design that significantly enhances space utilization. Unlike traditional cranes, underslung cranes are mounted on girders or roof structures, allowing for unimpeded vertical space below. A report from the Construction Industry Institute highlights that effective space management can lead to efficiency improvements of up to 30% on construction sites. This design feature is particularly beneficial in urban environments where space is limited, enabling contractors to maximize the use of their available area while reducing the footprint of their equipment.

Additionally, the flexibility of underslung cranes makes them ideal for complex construction projects requiring intricate lifting patterns and maneuverability. The European Construction Technology Platform indicates that projects that utilize advanced lifting solutions, such as underslung cranes, report faster project completion times by as much as 20%. By freeing up ground level space, these cranes facilitate easier access for other machinery and workers, further enhancing overall productivity and organization on-site. As construction demands evolve, the underslung crane's design allows for effective workflow management, contributing to significant cost savings and meeting project deadlines more efficiently.

| Benefit | Description | Impact on Space Utilization |

|---|---|---|

| Enhanced Workflow | Allows materials to be lifted and positioned quickly and efficiently. | Reduces the need for extensive ground space, maximizing usable area on the site. |

| Increased Lifting Capacity | Can lift heavier loads compared to traditional cranes, expanding capabilities. | Less equipment required on-site, conserving valuable space. |

| Versatility | Suitable for various lifting tasks in complex environments. | Flexible design reduces site preparation needs and space requirements. |

| Safety Improvements | Minimizes the risk of accidents by improving load control. | Reduces clutter and enhances safe movement on job sites. |

| Eco-Friendly Design | Lower energy consumption compared to conventional cranes. | Efficient use of space reflects sustainable building practices. |

Underslung cranes are increasingly recognized for their versatility across a range of construction tasks, making them an indispensable tool in modern engineering projects. Unlike traditional cranes that rely on ground support, underslung cranes are suspended from a structure, such as a beam or ceiling, allowing for unobstructed space below. This unique configuration is particularly beneficial in tight urban settings or inside buildings where space efficiency is critical. According to a report by the International Association of Crane and Rigging Professionals, the use of underslung cranes can improve operational efficiency by as much as 30% in environments that require precision and flexibility.

Moreover, underslung cranes cater to a wide variety of applications, from lifting heavy materials during the construction of high-rise buildings to facilitating intricate assembly processes in manufacturing plants. They are adept at navigating complex workplaces and can easily be integrated into existing structures, which can reduce the total project time significantly. A study published in the Journal of Construction Engineering highlighted that adopting underslung cranes led to a decrease in labor costs by approximately 20% due to faster load handling and reduced downtime. This adaptability not only helps in meeting tight deadlines but also enhances safety by minimizing the risk of collisions in crowded construction areas.

Utilizing underslung cranes in construction projects not only enhances operational efficiency but also presents significant cost-effectiveness. These cranes are typically installed under the structure, allowing for maximum use of overhead space and reducing the need for additional support structures. This space-saving design directly translates to lower overall project costs, as contractors can minimize material expenditures and streamline labor efforts.

When planning your construction project, consider these key tips: First, evaluate the workflow efficiency that an underslung crane can provide. Because these cranes offer superior maneuverability, they can reduce the time spent on moving materials, which can result in quicker project completion and reduced labor costs. Second, assess your site layout to determine if an underslung crane can optimize the available space, potentially allowing for a smaller footprint and less disruption to the surrounding area.

Moreover, the initial investment in an underslung crane can often be offset by the long-term savings generated from decreased maintenance costs and increased productivity. Implementing this technology can lead to fewer operational interruptions and a more streamlined process, ultimately enhancing profitability. Remember, understanding your project’s specific requirements can help you make the best equipment choice, ensuring projects remain on budget and on schedule.