Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

In the world of lifting solutions, the advantages of a Telescoping Crane cannot be overstated. Renowned expert, John Smith, once remarked, "The versatility of telescoping cranes revolutionizes material handling." This statement rings true as these cranes adapt to a variety of lifting tasks with ease.

Telescoping Cranes enhance efficiency in construction, manufacturing, and logistics. Their adjustable boom allows them to reach hard-to-access areas. However, choosing the right type can be challenging. With numerous options available, it’s essential to consider specific project requirements.

Despite their many benefits, users must remain vigilant. Over-reliance on automation in cranes can lead to oversight and safety risks. Understanding the limitations and proper usage of a Telescoping Crane is critical. The right choice can significantly improve lifting capabilities while ensuring a safer work environment.

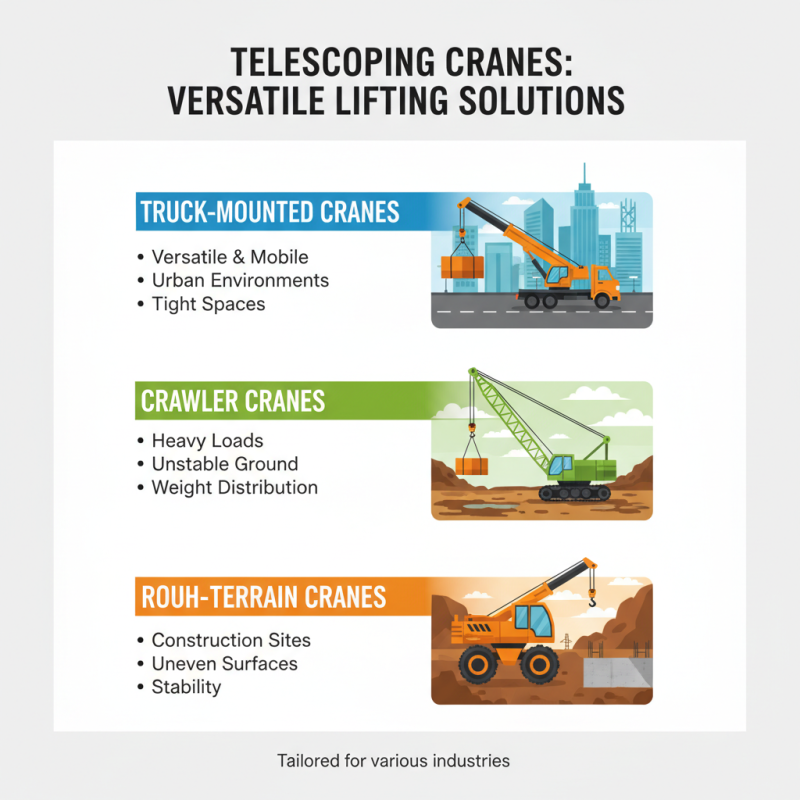

Telescoping cranes offer various lifting solutions tailored to different industries. The types available include truck-mounted, crawler, and rough-terrain cranes. Each type has unique capabilities. For instance, truck-mounted cranes are versatile and ideal for urban environments. They can navigate tight spaces with ease. Crawler cranes excel on unstable ground, distributing weight effectively. Rough-terrain cranes are designed for construction sites, offering stability on uneven surfaces.

Recent industry reports indicate that the global telescoping crane market is projected to grow by 5% annually. This growth stems from increased infrastructure projects worldwide. However, choosing the right type can be challenging. Factors like load capacity, reach, and job site conditions must be considered. Some companies overspend on cranes with unnecessary features.

Training operators can be a concern as well. Proper use of telescoping cranes prevents accidents. Unfortunately, many operators lack sufficient training. This oversight can lead to costly mistakes. Understanding strengths and limitations of each crane type is crucial for effective lifting solutions. Operators should assess their specific needs before making a choice. Making informed decisions enhances safety and efficiency in the long run.

Telescoping cranes are vital in modern construction. They provide flexibility and reach in tight spaces. A survey by the Machinery Industry Association indicates that telescoping cranes account for approximately 30% of all lifting equipment used on job sites. This high utilization shows their importance in lifting tasks.

One significant feature of telescoping cranes is their adjustable boom length. This allows operators to extend the crane's reach without moving the entire unit. This can save time and increase efficiency. Additionally, many models have advanced safety features, such as load moment indicators. These systems ensure that operators avoid overloading, which is a common concern in construction.

However, relying solely on these cranes may have drawbacks. Operators need proper training to manage their complex controls effectively. In some cases, poor maintenance can lead to mechanical failures. A report from Construction Equipment Safety Council highlighted that improper use led to nearly 25% of accidents involving cranes. Thus, while telescoping cranes offer numerous advantages, attention to detail is critical for safe and effective operation.

When choosing between fixed and mobile telescoping cranes, several factors come into play. Fixed cranes are often mounted on a permanent structure. They provide stability and can handle heavy loads. According to industry reports, fixed cranes can lift up to 400 tons. However, they lack flexibility and require more groundwork for installation.

On the contrary, mobile telescoping cranes offer versatility. They can easily move around job sites, which makes them ideal for construction where space is limited. These cranes typically lift between 20 to 200 tons, depending on the model. Data suggests that their mobility can increase productivity by up to 30%. However, they may face stability issues with heavier loads.

Tips: Always assess the site conditions. Consider load requirements carefully. Attachments matter, too. Choosing the right crane can prevent potential accidents. Evaluate if your project will benefit from fixed or mobile options. Understanding both helps refine lifting solutions and optimize efficiency for your needs.

| Crane Type | Load Capacity (tons) | Max Height (meters) | Mobility | Applications |

|---|---|---|---|---|

| Fixed Telescoping Crane | 10 | 15 | No | Construction, Warehousing |

| Mobile Telescoping Crane | 20 | 30 | Yes | Infrastructure Projects, Shipping |

| Mini Telescoping Crane | 5 | 10 | Yes | Tight Spaces, Residential Areas |

| Heavy-Duty Telescoping Crane | 50 | 40 | No | Industrial, Manufacturing |

When using telescoping cranes, safety is paramount. The construction industry reports that nearly 40% of crane accidents involve improper use. These incidents often lead to injury or even fatalities. Factors like operator training and equipment maintenance play crucial roles in ensuring safety. Regular inspections and proper operator certification can mitigate risks.

The design of telescoping cranes allows for flexible lifting. However, many operators overlook load limits. Lifting loads beyond specified limits can lead to tipping. The American National Standards Institute (ANSI) emphasizes adherence to load charts. These charts guide safe operations and help prevent accidents.

Additionally, environmental conditions can impact safety. Wind and ground stability are critical factors. For example, a gusty wind can make stability challenging. Operators must stay vigilant and assess conditions constantly. Despite the advanced technology in telescoping cranes, human error remains a key factor in safety breaches. Attention to detail and proper training are essential for effective lifting solutions.

Telescoping cranes play a vital role across various industries. In construction, they move heavy loads to great heights. They are perfect for tight spaces and can extend to reach distant objects. This flexibility is essential in urban areas where space is limited.

In the shipping industry, telescoping cranes efficiently load and unload containers from ships. They make it easier to handle heavy cargo. Operators need proper training. Improper use can lead to accidents.

**Tips:** Ensure regular maintenance checks. This can prevent equipment failures. Proper training is also crucial. All operators should know safety protocols. Investing in training can avoid costly mistakes.