Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

Choosing the right Heavy Duty Floor Crane can greatly impact efficiency in industrial settings. According to a report by the Machinery Industry Association, the market for these cranes is projected to grow by 7% annually through 2026. Companies are keen on maximizing productivity while ensuring safety.

“Every operation is unique. Selecting the right equipment is crucial,” says John Matthews, a heavy equipment expert with over two decades in the industry. His insight highlights the importance of understanding specific operational needs. For instance, weight capacity, height, and maneuverability are key factors to consider.

While options abound, not every Heavy Duty Floor Crane will meet every requirement. Some features may seem appealing but may not suit different environments. Reflection on your specific context is essential. Make informed decisions to enhance your workflow. Ultimately, a thoughtful selection process can lead to improved outcomes and better workplace safety.

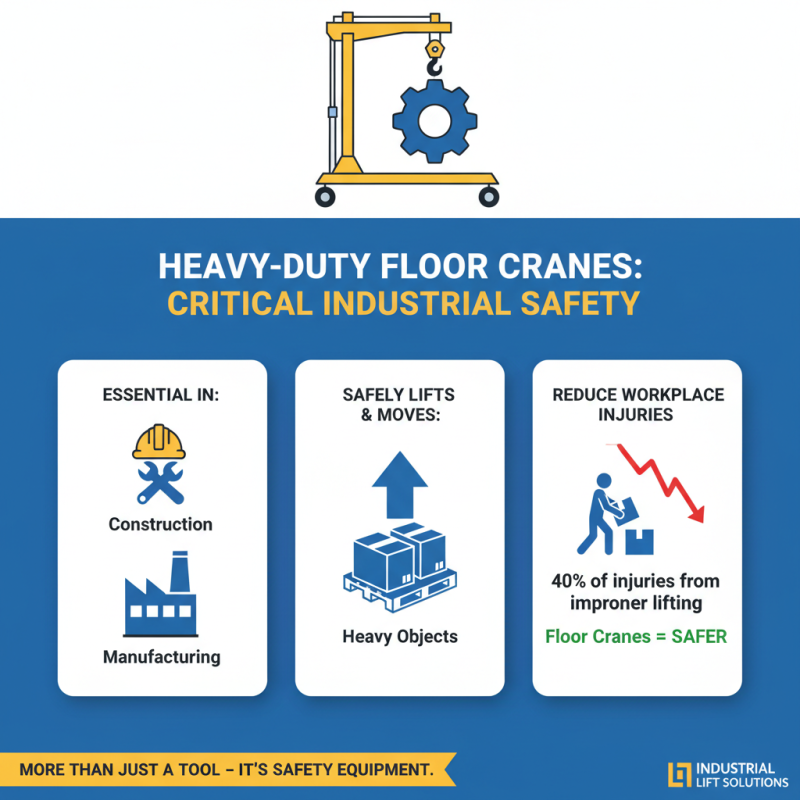

Heavy-duty floor cranes are essential in various industries, including construction and manufacturing. They are designed to lift and move heavy objects safely. According to industry reports, about 40% of workplace injuries are related to improper lifting techniques. Using a floor crane can significantly reduce these risks. They are not just tools; they are critical safety equipment.

When selecting a heavy-duty floor crane, consider its weight capacity and height range. Different models offer varying capabilities. A crane that lifts up to 5 tons may not suit a task requiring a lift of 10 tons. Ensure it meets your specific needs. Ergonomics also matters. Cranes should allow easy maneuvering in tight spaces.

**Tip:** Always check the crane’s specifications before purchasing. Look for features like a stable base and adjustable legs.

Additionally, training staff on using the crane is vital. Many accidents happen due to improper use. Regular training ensures everyone understands the safety protocols. According to the Occupational Safety and Health Administration (OSHA), up to 25% of all lifting accidents can be avoided with proper training.

**Tip:** Schedule regular training updates for your team. Emphasize the importance of safety with every lift.

When selecting a heavy-duty floor crane, several key features should be at the forefront of your decision-making process. Load capacity is critical. Most heavy-duty floor cranes can lift between 1,000 to 4,000 pounds. This range caters to various industrial applications. Ensure the crane you choose matches the weight requirements of your tasks.

Stability is another essential aspect. Look for cranes with wide bases and sturdy frame construction. A stable crane will minimize risks during operations. According to industry reports, over 30% of accidents in lifting operations happen due to equipment instability. This statistic emphasizes the importance of a solid design in your selection.

Tip: Always check the reach of the crane arm. It should be long enough to access your target loads effectively. Sometimes, a crane may have the right capacity but not the appropriate reach. This mismatch can lead to inefficiencies and frustration.

Additionally, consider ease of maneuverability. Many cranes feature wheels for easy movement. However, not all wheels are the same. Some may be suited for smooth surfaces, while others are designed for rough terrain. Make sure to assess the environment where the crane will be used.

| Feature | Description | Considerations |

|---|---|---|

| Weight Capacity | The maximum weight the crane can lift safely. | Choose a capacity that exceeds your heaviest item. |

| Reach | The distance the crane can lift and extend the load. | Ensure it meets the height and horizontal distance required. |

| Base Size | Dimensions of the crane base impacting stability. | Space available in your working area should be considered. |

| Mobility | Ease of moving the crane around the workspace. | Look for models with wheels and swivel casters. |

| Material | Construction material influences durability and weight. | Steel frames are generally more durable than aluminum. |

| Adjustability | Ability to change the height and reach. | Consider whether you need fixed or adjustable models. |

| Safety Features | Features such as locking mechanisms and overload protection. | Ensure the crane meets safety standards for operation. |

When choosing a heavy-duty floor crane, assessing lift capacity is crucial. This factor determines how much weight the crane can safely lift. Knowing your needs helps in making the right choice. Think about the heaviest load you will handle. Will it be a few hundred pounds or several tons? Exact specifications help to avoid future problems.

Reach is another key aspect. A crane with too short a reach may limit your options. Consider the dimensions of the items you will lift. They may not fit comfortably if the crane cannot extend far enough. Visualize your workspace. You want to ensure the crane can maneuver effectively. This often requires careful planning of the layout.

Don’t forget about stability. A heavy load placed incorrectly can tip the crane. Testing the crane with different loads can provide insight into its reliability. Look for feedback about the operating experience. Sometimes, adjustments are necessary after first use. Reflect on your choice to ensure it meets all your needs.

When choosing a heavy-duty floor crane, evaluating build quality and materials is essential. Look for sturdy construction that can withstand the demands of heavy lifting. Steel frames generally offer good strength and durability. Some cranes use aluminum, which is lighter but may lack the same load-bearing capacity. Pay attention to welds and joints as they can be weak spots.

Material choice affects both performance and longevity. A powder-coated finish can prevent rust and corrosion, extending the crane's life. Be cautious of cranes made with cheaper materials; they may not hold up under stress. Examine the wheels, too. High-quality wheels provide better mobility and stability.

Tips: Always check weight ratings. A crane should exceed your expected load. Look for adjustable arms. Flexibility can enhance usability and safety. Lastly, read reviews or seek feedback. Real user experiences offer valuable insights. Too often, people overlook these details and regret their choices later. Reflect on what works best for your specific needs.

Selecting a heavy-duty floor crane requires careful attention to safety considerations. It is crucial to ensure the crane meets all relevant compliance standards. Familiarize yourself with Occupational Safety and Health Administration (OSHA) guidelines. These rules ensure operator safety, load limits, and equipment stability.

Prioritize safety features like overload protection and stability checks. Many cranes are equipped with designed safety mechanisms. However, always conduct regular inspections. Look for signs of wear and tear. Small issues can escalate quickly. If something seems off, address it immediately.

Training for operators is another essential factor. Proper training minimizes accidents. Operators should know how to handle different loads effectively. They should also understand the importance of clear signaling during operations. Communication is key. Reflect on your safety protocols regularly. Always ask: is there room for improvement?