Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

Choosing the right Cantilever Gantry Crane can significantly impact your operations. With various models available, it’s essential to understand your specific needs. The right crane improves efficiency and safety.

When looking for a Cantilever Gantry Crane, consider load capacity and height. Each project has unique requirements. For instance, construction sites may need cranes that can handle heavy loads and operate in tight spaces. Additionally, mobility is a key factor. A fixed crane limits your work area.

Some people overlook important details. Are you considering the weather conditions? Outdoor cranes may require special features to withstand elements. Reflecting on these details can enhance your decision-making process. As you weigh your options, remember that the best choice is one that aligns with your operational demands and budget.

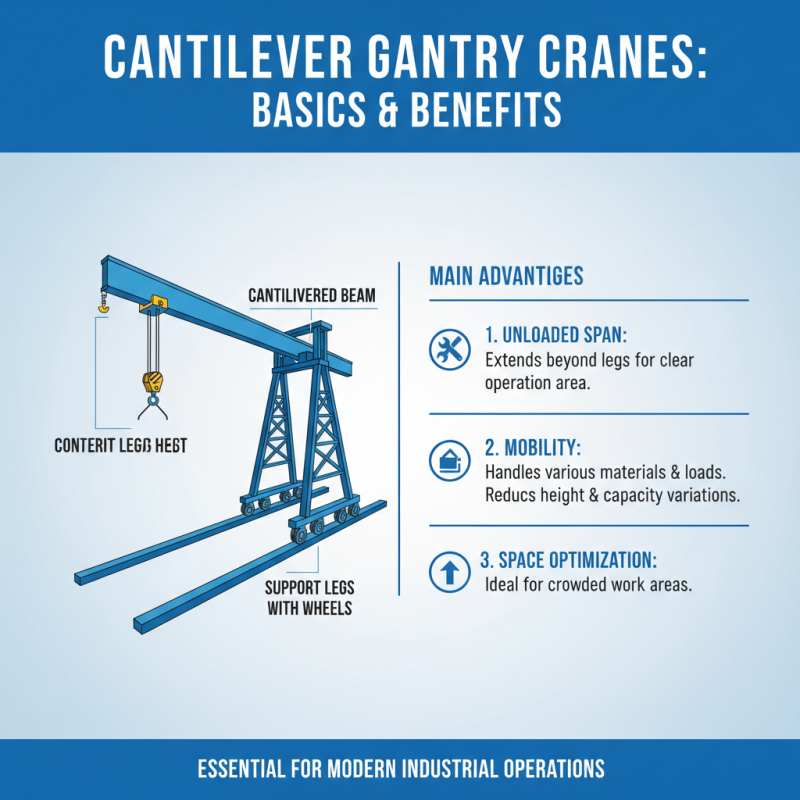

Cantilever gantry cranes are essential in various industries for their versatility and efficiency. Understanding the basics of these cranes is crucial when selecting the right one for your needs. A cantilever gantry crane typically comprises a beam supported by vertical legs, providing a clear span for operations. This setup allows it to move materials without major obstructions.

According to industry reports, the global market for gantry cranes is projected to grow significantly. The expected growth rate is around 4.5% annually through 2025. This indicates an increasing demand that highlights their importance in material handling. These cranes are especially useful in construction and shipping, where heavy loads must be maneuvered with precision. Users must consider load capacity, span length, and the height of the lift when choosing a crane.

It’s worth noting that not all projects require the same specifications. A common mistake is underestimating the required lifting capacity or failing to account for environmental conditions. Cranes operate differently based on surface stability or weight distribution. Proper assessments can prevent costly mistakes. Hence, a deep understanding of your operational needs and challenges is necessary for effective crane selection.

When choosing a cantilever gantry crane, load capacity is crucial. Understand the weight of your materials. Each application is unique, requiring specific configurations. A crane that handles too little may lead to accidents. Overloading can also cause mechanical failures. Assess your maximum expected load carefully.

Consider the types of items you lift. Heavy machinery needs support; lighter items require different specifications. It's vital to think beyond one-time lifts. Regular usage might mean upgrading to a stronger model. Don't forget safety factors. Loading and unloading zones are often uneven or cluttered. Choose a crane that handles these challenges effectively.

Think about future needs. Will your operations expand? If so, you may need a crane with a higher capacity. Reflect on your current setup, too. If it feels inadequate now, it likely will in the future. Stay proactive in evaluating your load requirements. This can prevent costly mistakes down the line.

Choosing the right cantilever gantry crane begins with understanding height and span requirements. Height is crucial for maneuverability. Industry standards suggest a minimum height of 12 feet for most applications. This allows enough clearance for safe operation, particularly in manufacturing and shipping environments. However, elevated surfaces or existing structures may necessitate adjustments. Always evaluate the maximum lifting height needed for your specific tasks.

Span refers to the distance the crane can cover. According to industry reports, a span typically ranges from 10 to 40 feet. This range suits various needs but may not fit unique projects. Oversized loads require wider spans. The American Crane and Hoist Association recommends considering future expansions or changes in operations.

Adjusting height and span impacts crane performance significantly. A span too narrow can limit efficiency. But a wider span also increases complexity and stability concerns. Findings from multiple studies indicate that cranes with adjustable spans can provide flexibility. This adaptability is vital in dynamic work environments. Ultimately, balancing height and span requirements while factoring in operational demands is essential for effective crane selection.

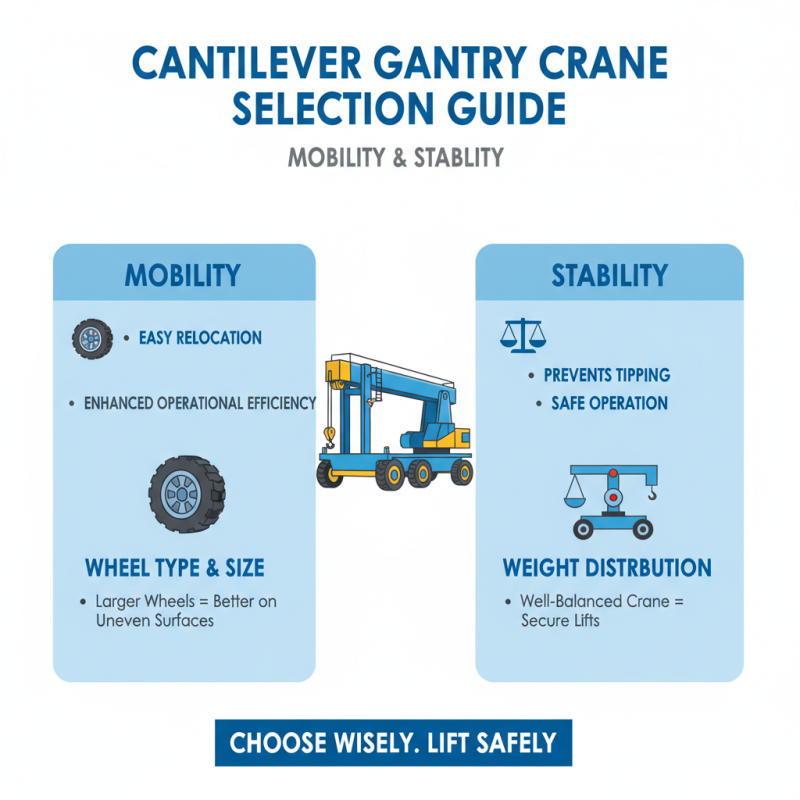

When choosing a cantilever gantry crane, mobility and stability become crucial factors. Mobility allows the crane to relocate easily, enhancing operational efficiency. Consider the wheel type and size. Larger wheels perform better on uneven surfaces. Also, look at the crane's overall weight distribution. A well-balanced crane ensures stability during operation. You don’t want it tipping over during a lift.

Stability features are vital for safety. Check the base design; a wider base offers more stability. Some cranes have adjustable legs. This can help adapt to different surfaces but can also be tricky. It requires constant monitoring to ensure they are properly set. The materials used can also affect stability. Metal frames tend to be sturdier but can add weight. Lightweight materials may enhance mobility, but at what cost to stability?

Finally, consider the environment. Indoor use might prioritize different features compared to outdoor settings. Wind can sway the crane, especially for taller models. If the crane is too mobile, it may compromise stability. It’s essential to reflect on these factors carefully. Ensuring your choice meets both mobility and stability can lead to safer operations.

When selecting a cantilever gantry crane, material and construction quality are vital for longevity. Poor quality materials can lead to frequent maintenance and safety issues. High-grade steel frames resist wear and tear better. The choice of components affects the entire crane's performance. Some manufacturers cut costs by using inferior materials, resulting in shorter life spans.

Tips: Look for cranes with corrosion-resistant coatings. This feature adds extra protection. It’s worth investing in durable wheels. They ensure smooth movement and stability.

Always consider the crane's structure. A robust design can withstand heavy loads and harsh environments. Additionally, inspect welds and joints for soundness. Weak points can lead to failure during operation. It's easy to overlook these details in the buying process, but they are crucial.

Remember to review customer feedback on material quality. Real user experiences can reveal hidden flaws. These insights are invaluable for informed decisions. Longevity hinges on these factors, so take the time to research.