Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

Choosing the right slewing crane for your construction project can be challenging. Many factors come into play. The specific needs of your job site dictate your choice. Slewing cranes come in various types and sizes. Understanding their features is essential.

Weight capacity is a crucial consideration. Some projects require lifting heavy loads. Other tasks involve lighter materials. Consider the height and reach you need too. A crane with a longer boom may be necessary for tall structures.

Furthermore, safety features are vital. A reliable slewing crane should include mechanisms to prevent tipping. Evaluate the operational environment as well. Outdoor sites may have different requirements than indoor ones. Inadequate planning can lead to costly mistakes. Reflect on your needs and resources. This ensures you select the best slewing crane for your project.

When selecting a slewing crane for construction, understanding its types is crucial. There are several varieties: tower cranes, mobile cranes, and crawler cranes. Each has distinct advantages depending on the project requirements. For instance, tower cranes are ideal for high-rise buildings, offering great height and lifting capacity. According to industry reports, tower cranes can lift loads up to 18 tons, making them a popular choice for large-scale projects.

Mobile cranes provide flexibility. They can be moved easily between sites. However, they often have a lower lifting capacity than tower cranes. The maximum load for mobile cranes can range from 10 to 50 tons. This variability makes them suitable for various tasks, but not always for heavy-duty lifting needed in extensive construction operations.

Reflecting on the data, project managers often overlook specific site conditions. Factors like soil stability and overhead obstacles can impact crane performance. Additionally, relying solely on lifting capacity may lead to safety risks. Choosing the right slewing crane requires a balance of load capacity, site conditions, and project scope. Ignoring these can lead to inefficiencies and potential accidents, underscoring the need for thorough assessment.

Choosing the right slewing crane is vital for any construction project. One key factor is the load capacity. Ensure the crane can handle the heaviest loads on site. Balance is also crucial. If the weight is too far from the center, the crane might tip over.

Another important step is considering the height restrictions. Check the maximum lifting height needed at your site. A crane that cannot reach the necessary height can cause serious delays. Think about the terrain as well. Rough or uneven ground can affect the crane’s stability.

Don't overlook additional features. Some cranes have advanced safety measures. Others may offer better maneuverability. Consider your project’s specific needs. An inappropriate choice may lead to safety risks or inefficiencies. It’s okay to seek advice. Experts can provide insights on what will work best.

| Factor | Description | Importance Level |

|---|---|---|

| Load Capacity | The maximum weight the crane can lift, which is critical to ensure it meets construction demands. | High |

| Reach | The maximum distance from the center of the crane to the farthest point it can reach. | Medium |

| Height | The total height of the crane, which should accommodate the construction site's height requirements. | High |

| Mobility | The crane's ability to move around the site, which affects efficiency in construction projects. | Medium |

| Operating Environment | The conditions in which the crane will operate, including weather and site layout considerations. | High |

| Safety Features | Safety mechanisms in place to prevent accidents and ensure operator and worker safety. | Very High |

| Cost | The total purchase or rental cost, which should align with the project's budget. | High |

When choosing a slewing crane, understanding load capacity and reach is vital. Load capacity refers to the maximum weight the crane can lift safely. According to industry reports, cranes can typically handle loads ranging from 5 to 1,000 tons. A project that requires lifting heavy materials will need a crane with a higher capacity. However, overestimating your needs can lead to unnecessary costs.

Reach is also a critical factor. It indicates how far the crane can extend its boom. Some cranes offer a reach of up to 50 meters, while others may only extend 10 meters. A longer reach is beneficial for sites with obstacles or where materials need to be placed at significant distances. Be cautious, though; cranes with extensive reach may sacrifice stability.

Evaluate your specific project requirements carefully. Consider the weight of materials and the layout of the construction site. Balance the need for capacity and reach against the potential for increased complexity and operational costs. Reflect on the potential for equipment downtime if the selected crane does not meet your precise needs. This evaluation will help ensure that your choice aligns with both safety standards and project timelines.

This bar chart compares various slewing cranes based on their load capacities and reach capabilities. Crane A to Crane E represent different models, with their respective load capacity in tonnes and reach in meters. This information assists in selecting the appropriate crane for specific construction needs.

When selecting a slewing crane, safety features should be a top priority. These machines must comply with strict safety standards. Operators and workers rely on the crane’s design to prevent accidents. Consider features like overload protection and emergency stop systems. These can significantly reduce risks on site.

Another important factor is the crane's stability. Watch for designs that provide a low center of gravity. Stability enhances safety, especially during heavy lifts. Regular inspections are necessary to ensure functionality. Outdated machinery can be a major liability. Always check compliance with local regulations. This can involve licenses, certifications, and regular maintenance logs.

It's easy to overlook the importance of training as well. Operators need proper education on safety practices. Without training, even the best cranes can pose dangers. Reflecting on past incidents can highlight gaps in knowledge or experience. Prioritize ongoing training to improve safety culture. A well-informed team can greatly enhance safety outcomes.

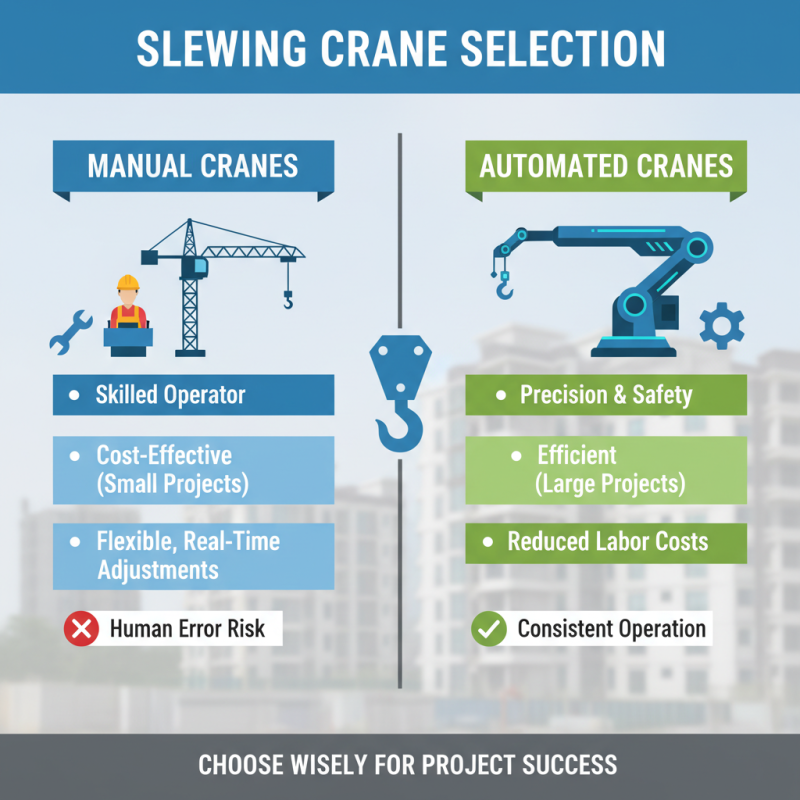

When considering a slewing crane for construction, the choice between manual and automated options is crucial. Manual cranes often require skilled operators and can be cost-effective for smaller projects. They allow for quick adjustments in real-time, making them flexible for various tasks. However, their reliance on human operators increases the potential for human error, which might lead to costly delays.

On the other hand, automated slewing cranes have become increasingly popular in large-scale operations. A report by the International Journal of Construction Technology states that automated systems can increase efficiency by up to 30%. These cranes reduce human error and improve safety on job sites. Yet, the upfront costs can be significantly higher, which might not suit every budget or project scale.

Choosing between these options requires reflection. Will a manual crane suffice for a smaller job? Or does your large project demand the efficiency of automation? Each choice comes with its drawbacks and potential advantages. Evaluating your specific construction needs will help make the right decision and optimize operational efficiency.