Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

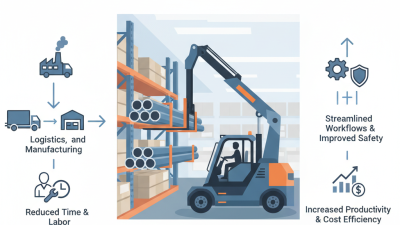

In the modern industrial landscape, the quest for efficiency and safety in lifting solutions has never been more critical. One of the standout technologies that have emerged to meet these demands is the Electric Monorail Hoist. These sophisticated devices not only enhance productivity but also ensure the secure handling of materials in various environments, from warehouses to construction sites. With their ability to cover vast distances and perform various lifting tasks, Electric Monorail Hoists provide a versatile solution for heavy-duty operations.

In this article, we will explore the top 10 Electric Monorail Hoists that are revolutionizing the way industries approach lifting challenges. We will delve into the features that make these hoists efficient, their operational benefits, and how they can significantly improve workflow while minimizing labor costs. By understanding these leading electric monorail hoists, businesses can make informed decisions that align with their operational needs and safety standards, paving the way for a more productive work environment.

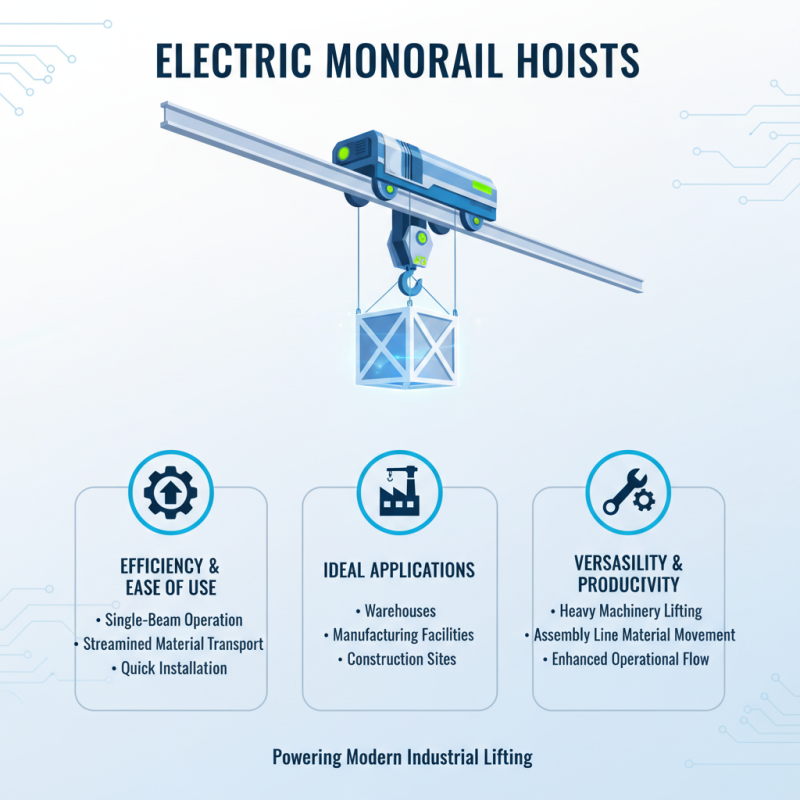

Electric monorail hoists are becoming increasingly popular in various industries due to their efficiency and ease of use. These hoisting systems operate on a single beam, providing a streamlined method for lifting and transporting materials across a horizontal plane. Their design allows for quick installation and minimal space utilization, making them ideal for warehouses, manufacturing facilities, and construction sites. Applications range from lifting heavy machinery during maintenance to moving large loads in assembly lines, showcasing their versatility in enhancing operational productivity.

When selecting an electric monorail hoist, it's essential to consider the load capacity, speed, and the environmental conditions it will operate in. Ensure that the hoist is compatible with your existing structures and meets safety standards. Additionally, regular maintenance and inspection are vital to ensure optimal performance and longevity.

Tips: Always consult with experts in the field to evaluate which monorail hoist system best fits your specific needs. Training your team on safety protocols and proper operation techniques will significantly reduce the risk of accidents and equipment damage. Consider implementing a tracking system to monitor hoist usage and schedule periodic maintenance checks.

When selecting an electric monorail hoist, several key features play a crucial role in ensuring safe and efficient lifting solutions. First and foremost,

lifting capacity is paramount; understanding the required weight limit for your applications is essential.

According to a recent industry report, over 40% of accidents in lifting operations are attributed to exceeding the hoist's specified capacity.

Therefore, assessing the load requirements based on your specific tasks can lead to significantly improved safety outcomes and operational efficiency.

Another critical consideration is the hoist's speed and control features. A hoist that offers variable speed options can enhance precision during lifting and lowering processes.

Up to 30% of downtime in warehouse operations is related to inefficient lifting practices, making responsiveness and control capabilities vital for maintaining productivity.

Additionally, consider the design and build quality, focusing on materials that resist wear and corrosion, as this enhances the lifespan and reliability of the hoist in demanding environments.

Tips: When evaluating different electric monorail hoists, prioritize models with built-in safety features such as overload protection and emergency stop mechanisms.

It’s also advisable to analyze the ease of installation and maintenance requirements, as this can affect long-term operational costs.

Lastly, consult with industry experts or use simulation software to model potential applications, which can provide valuable insights into optimal hoist selection for various lifting tasks.

When evaluating electric monorail hoists, a comprehensive comparison entails analyzing key specifications that cater to various industrial needs. According to the Global Hoist Market report, the electric hoist segment is projected to reach a market size of approximately $3.5 billion by 2025, driven by increasing demand for efficient and safe lifting solutions across construction, manufacturing, and warehousing sectors. This growth underscores the importance of selecting the right hoist that provides optimal lifting capacity, speed, and durability.

Efficiency is a critical factor in choosing electric monorail hoists. A study by the American Society of Mechanical Engineers indicates that electric hoists can improve operational efficiency by as much as 30% compared to manual lifting systems. Key performance metrics to consider include load capacity, lifting height, and speed, which can significantly affect productivity rates. Additionally, safety features such as overload protection and emergency stop mechanisms should not be overlooked, as they are pivotal in minimizing workplace accidents and ensuring compliance with safety regulations. By examining these factors, industries can make informed decisions that align with their lifting requirements while enhancing overall efficiency.

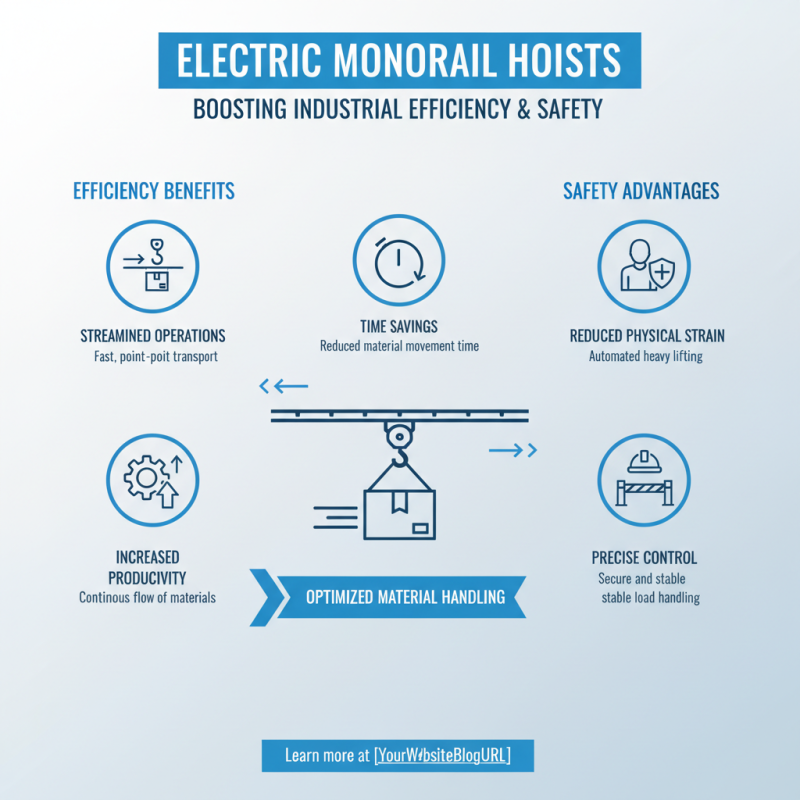

Electric monorail hoists have become increasingly popular in industrial settings due to their numerous benefits that enhance efficiency and safety in material handling processes. One of the primary advantages of these hoists is their ability to streamline operations. By utilizing a monorail system, businesses can easily transport heavy loads over long distances without the need for multiple lifting devices. This not only reduces the time taken to move materials but also minimizes the physical strain on operators, leading to increased productivity and a safer work environment.

Moreover, electric monorail hoists offer precise control and versatility in lifting applications. They are equipped with advanced technology that allows for smooth and accurate positioning of loads, which is critical in environments where precision is paramount. This level of control also translates to improved safety, as the risk of accidental drops or misalignments is significantly reduced. Additionally, the integration of these hoists into existing infrastructure is often seamless, as they can be installed in various configurations to fit the specific needs of an industrial setting. Overall, the adoption of electric monorail hoists represents a modern approach to lifting solutions that caters to the demands of today's industrial operations.

Electric monorail hoists are an essential component in various industries, providing efficient lifting solutions to streamline operations. However, to ensure these machines operate effectively over their lifespan, proper maintenance is crucial. According to a report from the Material Handling Industry of America, equipment downtime can be reduced by up to 25% through regular maintenance checks, considerably improving productivity and reducing costs.

One critical maintenance tip is to conduct routine inspections of the hoist components, including hooks, ropes, and electric controls. It’s recommended to perform these inspections at least once every six months, depending on the usage frequency. Keeping an eye out for wear and tear can prevent minor issues from escalating into significant problems, which, according to a study by the National Institute for Occupational Safety and Health, can cost companies thousands of dollars in repairs and lost revenue.

Additionally, ensuring that the hoist is adequately lubricated is vital for smooth operation. A lack of lubrication can lead to friction wear, which diminishes performance and efficiency. It's advisable to follow the manufacturer's guidelines on lubrication schedules and types of lubricants to use, as this can extend the life of the hoist. Implementing these maintenance tips not only helps maintain operational efficiency but also upholds safety standards within the workplace.

This chart represents the lifting capacity (in tons) of the top 10 electric monorail hoists on the market. By analyzing the data, users can determine which hoists are the most efficient for their lifting needs.