Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

In the world of equipment maintenance, spare parts play a critical role. They are essential for ensuring optimal performance and longevity of machinery. Without the right spare parts, even the most advanced equipment can underperform or fail.

Understanding which spare parts you need is vital. For instance, routine wear and tear can affect critical components. Ignoring these parts can lead to costly downtime and repairs. Investing in high-quality spare parts can make a significant difference. It’s important to note that not all spare parts are created equal. Some may be subpar, leading to further complications.

Evaluating your equipment’s needs is an ongoing process. You might find that some parts require more frequent replacements. This realization can be challenging. However, being proactive can prevent bigger issues down the line. So, prioritize learning about the spare parts specific to your equipment. Choose wisely to maintain peak performance.

When it comes to maximizing equipment efficiency, having the right spare parts is crucial. Key components like filters, belts, and bearings can dramatically impact performance. Regularly replacing these parts prevents unexpected breakdowns. Spare parts should be compatible with your equipment for optimal results.

Consider the filters. They keep contaminants out of essential systems. Dirty filters can lead to inefficiencies. Belts, on the other hand, assist in power transmission. A worn-out belt can cause your equipment to lag. Even small details, like sealants or gaskets, matter. They help maintain system integrity by preventing leaks.

It's easy to overlook these vital parts. Neglecting maintenance can lead to more significant issues. Developing a routine check for spare parts is essential. Think of each component as a piece of a larger puzzle. If one part fails, the whole system can struggle. Being proactive today can save you headaches tomorrow.

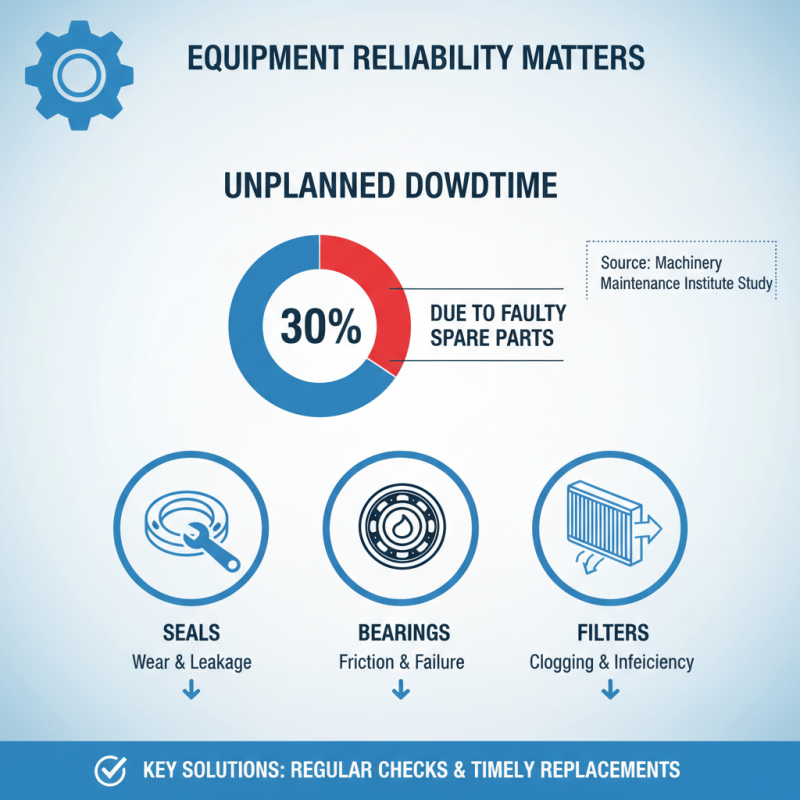

Maintaining equipment performance hinges on critical components that require attention. According to a study by the Machinery Maintenance Institute, nearly 30% of unplanned downtime is due to faulty spare parts. This statistic underscores the importance of regular checks and timely replacements. Components such as seals, bearings, and filters often wear out, leading to decreased efficiency.

Tips for keeping your equipment running smoothly include monitoring wear levels on essential components. Regularly inspect seals and replace them as needed. Schedule filter changes based on usage metrics. Small adjustments can lead to significant improvements in performance.

However, many operators overlook the significance of these parts. Ignoring minor issues can escalate into major failures. The consequences can be costly downtime and repairs. Make it a practice to document maintenance schedules. This can help prevent issues from snowballing. It’s crucial to reflect on past incidents to avoid future problems.

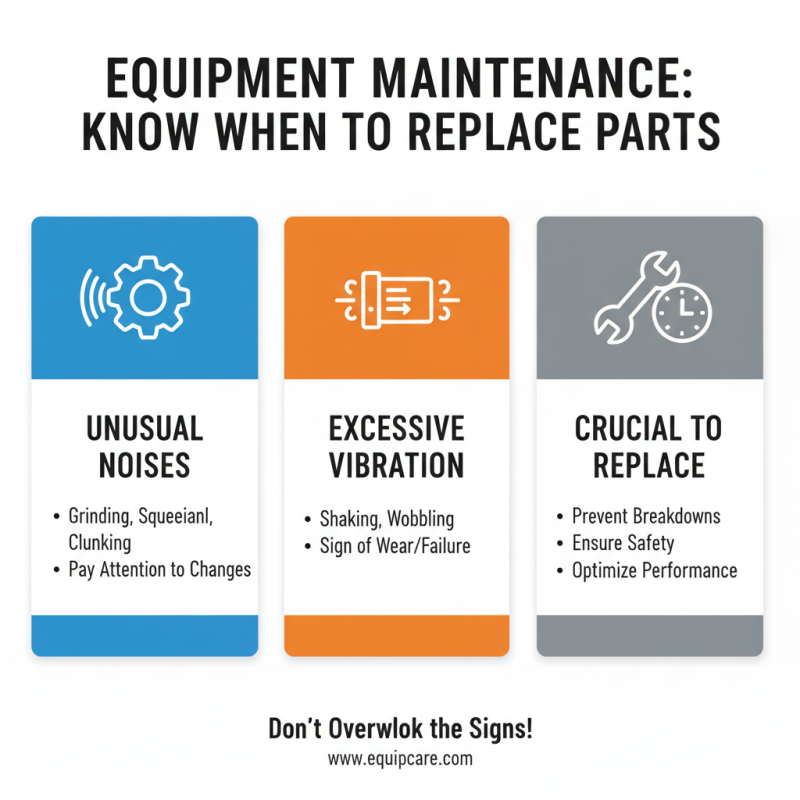

When it comes to equipment maintenance, knowing when to replace parts is crucial. Many operators overlook the signs that indicate a need for replacement. Unusual noises often signal that something is wrong. If your equipment starts to sound different, pay attention. Vibration can also indicate wear. Excessive shaking may mean a part is failing.

Another common sign is a decrease in performance. If the equipment you rely on no longer operates efficiently, it might be time for a change. Check for leaks as well. Fluid leaking from machinery can lead to bigger issues down the line. Lastly, inspect components regularly. Wear and tear happen gradually, making it easy to miss. However, proactive checks can prevent major breakdowns and costly repairs.

Sometimes, we dismiss minor issues. Ignoring them can lead to larger problems that are much harder to fix. Reflect on your maintenance routine. Are you attentive to the signs? Each small detail matters and can impact overall performance. Make a habit of regular inspections, so you catch these signs early. A little awareness goes a long way in keeping your equipment running smoothly.

Effective spare parts management is crucial for maximizing equipment performance. According to a recent report by the International Society of Automation, businesses can reduce downtime by up to 30% with proper inventory strategies. This emphasizes the need for organizations to maintain an optimal balance of necessary parts. Relying on outdated inventory systems often leads to overstock or stockouts, hindering productivity.

Regular audits and reviews of inventory levels can help identify critical components that require immediate attention. The Institute of Supply Chain Management suggests that 38% of companies face challenges due to inefficient spare parts tracking. Implementing a data-driven approach can streamline operations. Tracking usage patterns helps in anticipating demands accurately. A simple inventory management software can decrease errors significantly.

Yet, many organizations neglect training staff on these systems. Overlooking this aspect can result in costly mistakes. It's essential to foster a culture of continuous improvement. Engaging employees in inventory management processes creates accountability. Addressing gaps in communication also plays a pivotal role in ensuring parts are readily available. In this evolving landscape, reflecting on current practices is critical for achieving long-term efficiency.

Selecting quality spare parts for your machinery is crucial for optimal performance. According to industry reports, using subpar components can lead to up to a 25% decrease in machinery efficiency. When assessing spare parts, ensure they meet specifications for machinery type and intended use. Look for certifications that guarantee quality. This ensures longevity and prevents breakdowns.

**Tip:** Always check materials and manufacturing processes. Parts made from durable materials often last longer. Avoid choosing the cheapest option; investing in quality can save you money in the long run.

Another key factor is vendor reliability. Research suppliers thoroughly. Counterfeit parts are a growing issue, resulting in costly repairs and safety hazards. Be cautious when sourcing parts online; read reviews and verify authenticity.

**Tip:** Create a checklist when purchasing. Include aspects such as warranty, lead time, and return policy. A detailed approach can help you avoid common pitfalls.

| Spare Part | Description | Typical Uses | Quality Indicators |

|---|---|---|---|

| Hydraulic Filters | Removes contaminants from hydraulic fluid to ensure system efficiency. | Construction equipment, industrial machines. | Filtration rating, manufacturer specifications. |

| Bearings | Reduces friction between moving parts, enhancing operational efficiency. | Motors, conveyor systems, automotive applications. | Load rating, material quality. |

| Seals and Gaskets | Prevents the leakage of fluids and gases in machinery. | Pumps, engines, transmission systems. | Material durability, compression set resistance. |

| Belts and Chains | Transfers power within machinery while providing flexibility. | Motor drives, conveyor lines, agricultural equipment. | Tensile strength, wear resistance. |

| Electrical Components | Ensures proper function and communication of electrical systems. | Control panels, motors, sensors. | Voltage rating, thermal resistance. |