Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

In the world of material handling, the Cantilever Gantry Crane stands out as a versatile and efficient solution for various lifting tasks. As industrial operations continue to evolve, the importance of selecting the right crane becomes even more significant. Industry expert John Smith, a leading authority on lifting equipment, emphasizes, "Choosing the right Cantilever Gantry Crane is crucial to ensuring operational efficiency and safety in any project." His insights underline the necessity for businesses to consider several key factors that can impact both performance and safety.

When evaluating options for a Cantilever Gantry Crane, it’s essential to assess the specific needs of your operation, including load capacity, height adjustments, and workspace configuration. The selection process can be daunting, with numerous models and features available. However, understanding the fundamental aspects of crane mechanics, as well as the environment in which the crane will be used, can streamline the decision-making process. By adhering to expert recommendations and taking a systematic approach, businesses can make informed choices that enhance productivity while ensuring safety in their lifting operations.

Cantilever gantry cranes are versatile lifting solutions that play a crucial role in various industrial applications. Unlike traditional overhead cranes, these cranes feature a cantilevered arm design, allowing them to operate effectively in outdoor environments and in spaces where overhead structures may be limited. They are especially valuable in construction sites, shipyards, and warehouses, enabling the safe and efficient movement of heavy materials with ease. The open design also facilitates easy access for loading and unloading operations, making them an ideal choice for many logistical challenges.

In addition to their structural advantages, understanding the specific applications of cantilever gantry cranes is vital for selecting the right model for your needs. These cranes can be utilized for a range of tasks, including lifting and transporting heavy equipment, handling containers, and supporting maintenance activities. Factors such as load capacity, height restrictions, and mobility features should be considered based on the intended operational environment. By aligning the crane's capabilities with the specific requirements of the job, users can optimize productivity and safety, ensuring efficient workflow across various tasks.

When selecting a cantilever gantry crane, various key factors should be considered to ensure the best fit for your operational needs. First and foremost, the lifting capacity of the crane is paramount. Evaluating the maximum weight you intend to lift will help you determine the appropriate specifications. Additionally, consider the span of the crane. This refers to the distance between the legs of the gantry, and it should be matched to the layout of your workspace to allow ample room for maneuvering.

Another critical factor is the environment in which the gantry crane will operate. Assess whether the crane will be used indoors or outdoors, as outdoor cranes need enhanced weather resistance features. Furthermore, ease of mobility is a significant aspect; a crane that offers wheeled movement will provide greater flexibility for changing work locations. Lastly, don’t overlook the importance of safety features and compliance with local regulations to maintain a secure operating environment. Evaluating these factors thoroughly will enable you to make an informed decision and choose the right cantilever gantry crane for your specific requirements.

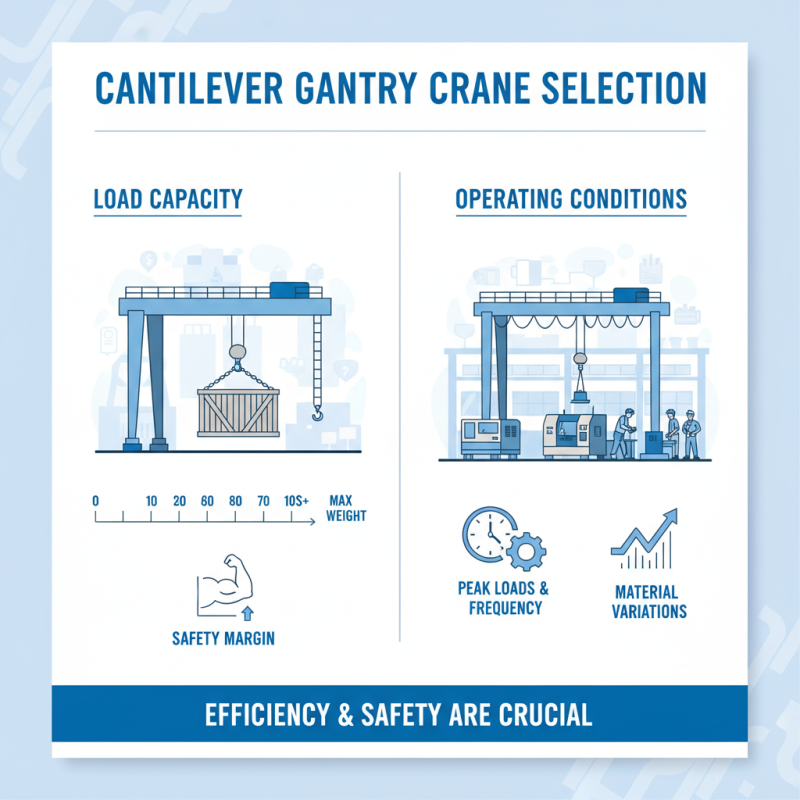

When choosing the right cantilever gantry crane, evaluating the load capacities and operating conditions is crucial for ensuring efficiency and safety. The load capacity of the crane is determined by the maximum weight it can lift without compromising stability. It's essential to assess the heaviest loads you expect to handle and factor in a margin to account for any variations in weight due to shifting materials or additional equipment. Understanding the specifics of your operations, such as peak loads and frequency of use, will guide you in selecting a crane with an adequate capacity to meet your needs over time.

Operating conditions play a significant role in determining the suitability of a cantilever gantry crane. Consider the environment where the crane will be used; for instance, outdoor cranes may need to withstand weather elements, while indoor cranes should accommodate height restrictions and floor conditions. The terrain and surface stability also impact the crane's performance; uneven or soft ground can lead to instability. Additionally, if your operations require maneuverability or adaptations for different tasks, ensure that the crane has the necessary features, such as adjustable heights and lateral movement, to comply with your specific requirements. Identifying these operating conditions early in your selection process will help in making a well-informed choice.

When selecting a cantilever gantry crane, prioritizing quality and safety features is crucial for ensuring operational efficiency and safeguarding personnel. According to the Occupational Safety and Health Administration (OSHA), incorrectly designed lifting equipment contributes to a significant portion of workplace injuries. In fact, nearly 36,000 injuries related to cranes occur annually in the United States alone, underscoring the necessity of choosing a crane that meets rigorous safety standards.

One key tip is to assess load capacity and stability. Ensure the crane's specifications align with your operational needs, factoring in the maximum load it will handle. Cranes with adjustable height and span provide greater versatility, but remember that they must be properly designed to maintain stability during operation. Secondly, inspect the safety features such as overload protection, emergency stop mechanisms, and limit switches. These components are vital for preventing accidents and ensuring that the crane operates within its safe parameters.

In tandem with evaluating design and safety features, another important aspect is the materials used in the construction of the crane. High-quality steel and corrosion-resistant finishes can significantly enhance durability and longevity, leading to reduced maintenance costs over time. A report by the Crane Manufacturers Association of America (CMAA) highlights that cranes made from superior materials can last up to 20% longer than their counterparts, showcasing the impact of quality on overall performance and safety.

When considering the purchase of a cantilever gantry crane, budgeting and cost factors play a crucial role in ensuring you make a financially sound decision. According to industry reports, the initial cost of a gantry crane can range significantly based on its lifting capacity, material quality, and manufacturer specifications. Typically, a small to mid-sized gantry crane may cost between $10,000 and $50,000, while larger, high-capacity models can exceed $100,000. This price variation underscores the importance of clearly defining your operational requirements before entering negotiations or making a final decision.

In addition to upfront costs, it’s vital to factor in ongoing expenses such as maintenance, operational costs, and potential training for staff. A study by the Material Handling Industry indicated that maintenance costs can represent up to 20% of a crane’s total lifecycle costs. Therefore, investing in quality equipment with a proven track record of reliability may lead to lower long-term expenses. Moreover, preparing a comprehensive budget that takes into account insurance, warranty options, and compliance inspections will provide a clearer financial picture, enabling better managerial decisions and ensuring longevity in your crane investment.

| Tip | Description | Estimated Cost Range | Key Considerations |

|---|---|---|---|

| 1. Define Your Needs | Assess the types of loads and environment to determine specifications. | $1,000 - $3,000 | Load weight, size, lifting height. |

| 2. Budget for Additional Features | Consider options like electric hoists, remote controls, etc. | $500 - $5,000 | Functionality vs. cost. |

| 3. Evaluate Space Requirements | Measure available space for crane footprint and height. | $1,000 - $2,000 | Clearance and maneuverability. |

| 4. Assess Load Capacity | Ensure the crane can handle maximum intended weight. | $3,000 - $10,000 | Safety margins and regulations. |

| 5. Determine Portability and Stability | Consider if a mobile or fixed crane is more suitable. | $2,000 - $6,000 | Site conditions and usage frequency. |

| 6. Review Safety Features | Look for features like emergency stops, limit switches, etc. | $500 - $3,000 | Compliance with safety standards. |

| 7. Check Maintenance Requirements | Assess how often the crane needs servicing and its cost. | $300 - $1,500 annually | Long-term cost implications. |

| 8. Request Quotes from Multiple Vendors | Getting several estimates can help negotiate a better price. | Varies significantly | Comparative analysis of offerings. |

| 9. Read Customer Reviews | Insight into the reliability and performance from users. | N/A | Product reputation and satisfaction. |

| 10. Consider the Resale Value | Think about how well the crane retains value over time. | $500 - $4,000 | Market trends and demand. |