Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

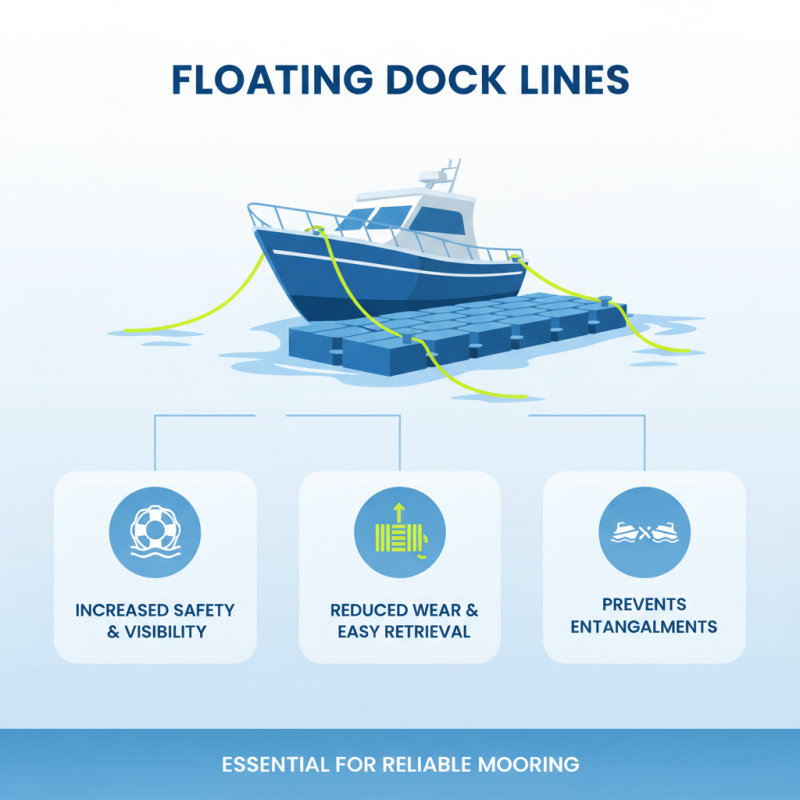

In the world of maritime activities, ensuring the safety and reliability of mooring solutions is of paramount importance. One essential component that plays a crucial role in this aspect is the use of Floating Dock Lines. These specialized mooring lines are designed to provide robust securement for vessels, helping to prevent accidents and damages caused by drifting or sudden weather changes. As such, selecting the right Floating Dock Lines can significantly impact the overall safety of boating experiences.

Floating Dock Lines come in various materials and designs, each tailored to meet the unique needs of different boat types and docking scenarios. From durable synthetic fibers to innovative buoyant designs, these lines not only enhance mooring stability but also facilitate easier handling and retrieval. Understanding the key features and benefits of Floating Dock Lines can empower boaters to make informed decisions that enhance their marine adventures while ensuring a secure and worry-free mooring experience.

As we delve into the top Floating Dock Lines available today, we will explore their distinct characteristics, advantages, and the factors to consider when choosing the right option for your specific needs. With this knowledge, boaters can confidently navigate the waters, knowing they have the most effective mooring solutions at their disposal.

Floating dock lines are an essential accessory for ensuring safe and reliable mooring solutions, especially for boats and vessels in various water environments. One of the primary benefits of using floating dock lines is their buoyancy, which prevents the lines from becoming submerged. This feature minimizes wear and tear, prolonging the life of the line and making it easier to retrieve when you need to untie your boat. Floating lines also allow for better visibility, which is crucial in crowded or busy marinas, ensuring that other vessels can see your mooring setup and reducing the risk of collisions.

When using floating dock lines, it’s important to consider a few tips for optimal performance. First, ensure that the lines are appropriately sized for your vessel. Using lines that are too thin or too thick can compromise safety during mooring. Additionally, maintaining the dock lines by periodically checking for fraying or damage can prevent potential failures during critical moments. Lastly, always secure the lines properly to the cleats or pylons to avoid slipping, and consider using additional knots or securing methods for extra protection during harsh weather conditions. These simple practices can enhance the reliability of your mooring situation significantly.

When selecting floating dock lines, safety and reliability should be paramount considerations. One key feature to look for is the material composition of the lines. High-quality dock lines are typically made from braided nylon or polypropylene, which offer excellent resistance to UV rays and saltwater corrosion.

According to industry reports, braided nylon is particularly favored for its strength and elasticity, with tensile strength often exceeding 20,000 pounds, ensuring that lines can withstand considerable force during adverse weather conditions.

Another vital characteristic is the line's diameter and length. A thicker line generally provides greater strength and durability, while the length can affect ease of use and flexibility during mooring. The American Boat and Yacht Council (ABYC) recommends that the line diameter should correspond to the size and weight of the boat, with a common guideline suggesting a diameter of at least 1/8 inch for every 10 feet of boat length. Additionally, features like built-in floats or reflective materials can enhance safety and visibility, especially in low-light conditions.

Investing in high-quality floating dock lines that meet these specifications will ensure a secure and dependable mooring solution.

When it comes to ensuring safe and reliable mooring solutions, understanding the types of floating dock lines and their specific applications is crucial. Floating dock lines are primarily categorized into three types: nylon, polypropylene, and polyethylene. Nylon dock lines are favored for their strength and elasticity, which can absorb shocks and minimize strain during turbulent weather conditions. According to recent industry reports, nylon lines exhibit a tensile strength that can withstand a load of over 5,000 pounds, making them ideal for larger vessels that may encounter rough waters.

Polypropylene lines, on the other hand, are known for their lightweight and buoyant characteristics, allowing them to float on water. This feature makes them particularly suitable for recreational boating and small watercraft, where ease of handling is essential. A study published by the Marine Mooring Association indicates that polypropylene dock lines can reduce the risk of entanglement and improve efficiency in dock operations by up to 30%. Lastly, polyethylene lines, while less common, offer superior UV resistance and durability, making them a viable option for long-term outdoor use. Their performance in harsh marine environments underscores their importance in the floating dock line market. Understanding these distinctions not only enhances safety but also contributes to the longevity and reliability of mooring setups.

Ensuring safe and reliable mooring solutions starts with the proper installation and maintenance of floating dock lines. According to a report by the American Boat and Yacht Council (ABYC), improperly installed dock lines are a leading cause of accidents and property damage in marine environments. To prevent these incidents, it is crucial to follow best practices when setting up dock lines.

First, always select dock lines that are appropriate for the size and weight of your vessel, as well as the environmental conditions. For example, lines made from nylon or polyester offer excellent strength and stretch, which can absorb shocks and reduce strain on both the dock and the boat.

Once the right dock lines are selected, installation requires attention to detail. It is recommended that dock lines be secured using proper knots, such as the cleat hitch or bowline, to ensure they hold under varying loads. Regular inspections are essential; the National Marine Manufacturers Association (NMMA) suggests checking dock lines for signs of wear—fraying, discoloration, or stretching—at least once a month.

If any degradation is observed, lines should be replaced promptly to maintain safety. Additionally, it is beneficial to store dock lines in a dry, shaded area when not in use to extend their lifespan and prevent material degradation. Adhering to these installation and maintenance practices will not only enhance safety but also ensure the longevity and reliability of your mooring solutions.

When it comes to ensuring the safety and reliability of your mooring solutions, the choice of floating dock lines is paramount. These lines are specifically designed to maintain the stability of boats and other watercraft, preventing them from drifting or colliding with impacts caused by waves or wind. High-quality floating dock lines are constructed with durable materials that enhance their strength and longevity, making them essential for both casual and professional marine enthusiasts.

Selecting the right floating dock lines involves considering factors such as elasticity, buoyancy, and UV resistance. Elasticity allows for give and flexibility, reducing the risk of snapping under strain. Meanwhile, buoyant lines help keep the mooring points visible and accessible, which is particularly important in busy marinas or for smaller vessels. Additionally, UV-resistant materials ensure that your lines will withstand the harsh outdoor elements, prolonging their useful lifespan. Various manufacturers offer floating dock lines tailored to diverse boating activities and environmental conditions, making it crucial to evaluate your specific needs before making a purchase.