Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

Floating Dock Lines play a crucial role in marine activities. These lines ensure the stability and safety of boats at docks. Yet, many boaters overlook their proper use, which can lead to accidents or damage.

Using Floating Dock Lines effectively requires understanding their materials and lengths. Choosing the right size is essential for various boat types. The lines must be neither too short nor too long. With the right tension, they provide necessary support. However, improper handling can cause slips or mishaps.

Being mindful of weather conditions is also important. Strong winds and waves can affect line performance. Are your lines adequately secured during adverse weather? This reflection can improve your docking experience. Remember, effective usage of Floating Dock Lines enhances safety and convenience at the dock.

Floating dock lines are essential for securing vessels at marinas or temporary moorings. They prevent boats from drifting, especially in windy conditions. Understanding their structure is key to using them effectively. Typically made of flexible materials, these lines float on water. This feature minimizes wear from rubbing against pilings or other boats.

When using floating dock lines, pay attention to their length. Lines that are too short may strain, leading to potential breakage. Too long can create tangles, which are frustrating. Regularly inspect your lines for signs of wear. A frayed line could snap during a storm, causing accidents. Also, the knots you choose matter. A weak knot can fail at critical moments. Practice tying strong knots to ensure your boat remains secure.

While floating dock lines offer convenience, their management is crucial. Many part-time boaters underestimate their importance. It's easy to overlook the simple details. Ensuring that lines are properly coiled and stored can prevent future complications. Take the time to understand your lines, and you'll improve your docking experience significantly.

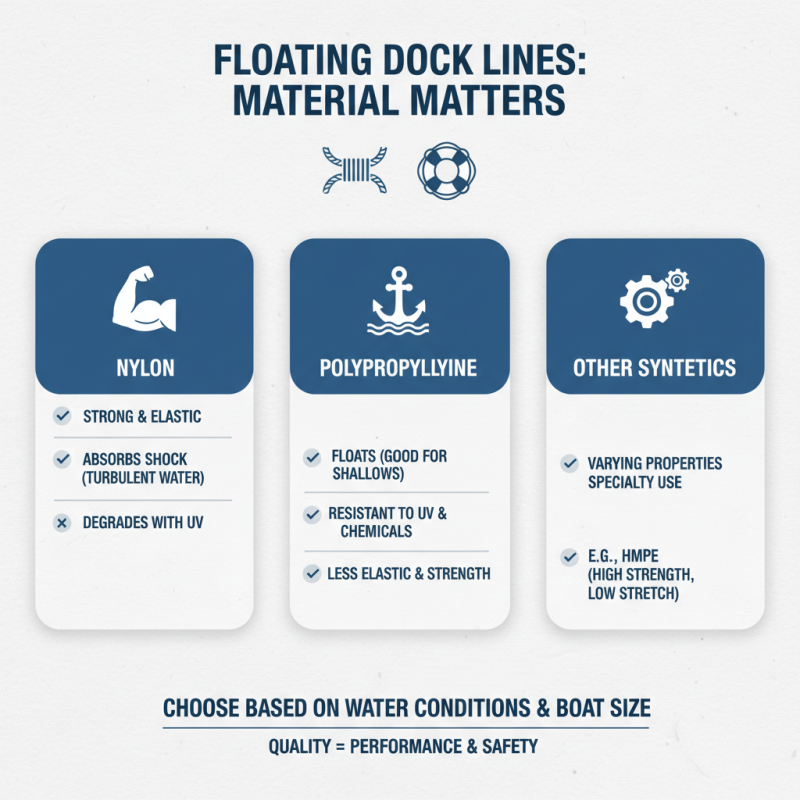

Choosing the right materials for floating dock lines is crucial for performance and safety. Many people overlook the importance of material quality. Options include nylon, polypropylene, and other synthetics. Each has its unique characteristics. Nylon is strong and elastic. It can absorb shock well, which is useful in tumultuous waters. However, it can degrade in UV exposure over time.

Polypropylene is lighter and floats, making it suitable for specific applications. It's less expensive but not as durable as nylon. Sometimes, using a weaker line can lead to accidents. A poor choice can mean the difference between safety and disaster. Many dock users regret not investing in higher-quality materials.

Local environmental conditions also play a role. Saltwater and sunlight can quickly wear down lines. Regular inspections help identify wear and tear. Paying attention to these details can prolong a line's life significantly. People often realize too late that cheap materials lead to frequent replacements. Reflecting on experiences can help in making more informed choices. Ultimately, the right material can enhance safety and reliability on the water.

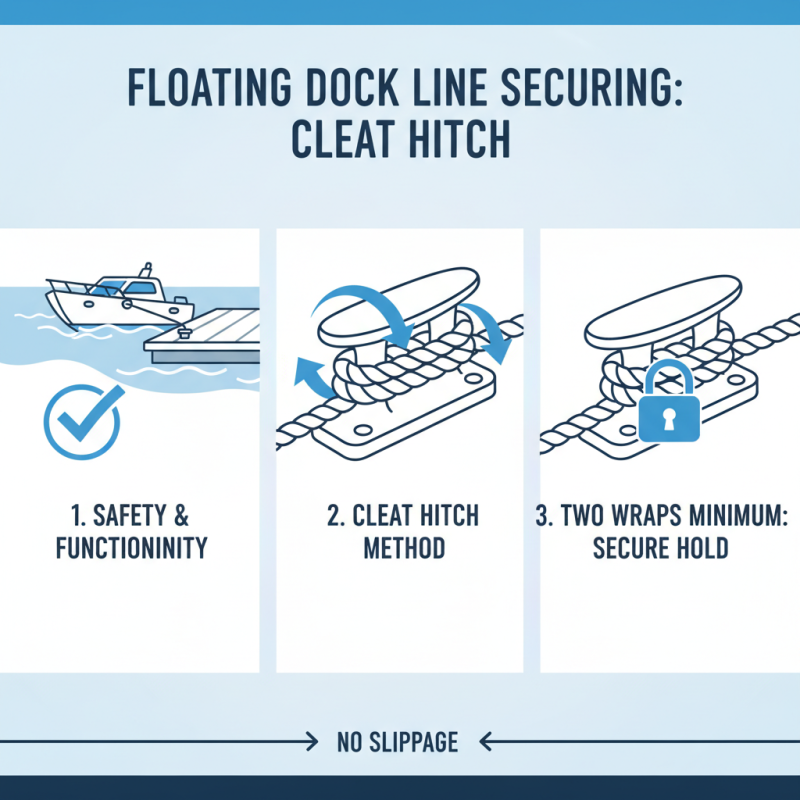

When securing floating dock lines, proper techniques are crucial for safety and functionality. One effective method is using a cleat hitch. This knot offers a strong hold and can withstand tension from wind or waves. Ensure the rope wraps around the cleat at least two times. This way, you create a secure connection without risking slippage.

Another important technique involves adjusting the line length. If the dock line is too loose, it can cause the dock to move excessively. However, overly tight lines can lead to wear and eventual breakage. Finding a balance is essential. Consider checking the lines regularly, especially after storms or high winds. It's easy to overlook worn areas or fraying, but this can lead to unexpected failures.

Despite best efforts, mistakes can happen. Sometimes, knots may come undone or lines may weaken. Always have a backup plan in place. Keeping spare lines on hand can save time and frustration later. Regularly reviewing your docking setup and techniques can prevent issues before they arise.

Maintaining floating dock lines is crucial for their longevity and performance. Regular inspections can help catch wear and tear early. Look for frayed edges or signs of stretching. Taking action promptly can prevent bigger issues later.

Here are some tips to keep your dock lines in good condition. Store them properly when not in use. A cool, dry place works best. Avoid leaving them exposed to sunlight for long periods. UV rays can weaken fibers over time. Clean your lines regularly. Rinse off salt and grime after each use.

Consider replacing lines when you notice significant wear. It's tempting to hold on to them longer. But safety should always come first. Investing in newer lines may save you from future accidents. Even minor tears can lead to bigger problems. Regular maintenance will save you time and money.

When using floating dock lines, safety is paramount. Floating docks can be challenging in rough waters. According to industry reports, nearly 30% of accidents occur due to improper line handling. Awareness is key.

Tips: Always keep a close eye on your surrounding environment. Weather changes fast. Wind and tides can affect your dock lines significantly.

To ensure safety, use high-quality materials that resist wear and tear. Regularly inspect your dock lines for fraying or knots. Surprisingly, many users neglect this. A worn line can snap under pressure, causing accidents.

Tips: Proper tying techniques are crucial. Use secure knots that can withstand tension. The right knot can prevent lines from slipping. Don't rush this process; take your time to tie them correctly. Lack of attention here can lead to injuries.