Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

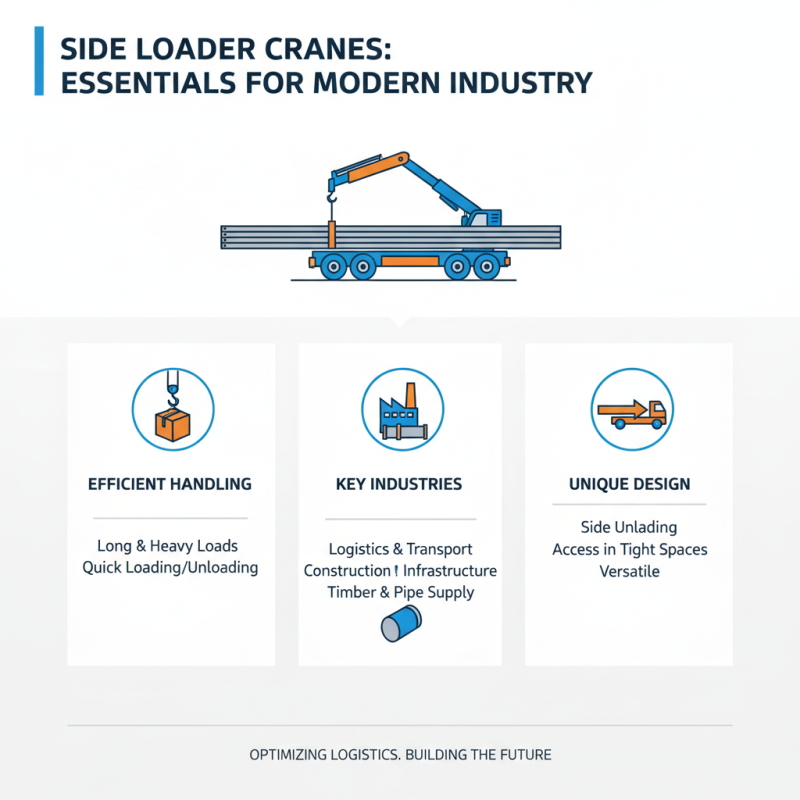

The Side Loader Crane is an essential piece of equipment in various industries. Its unique design allows for efficient loading and unloading of goods in tight spaces. Many businesses benefit from its versatility and maneuverability.

This crane is specifically crafted to handle long or bulky items with ease. It minimizes the risk of damage to cargo and improves overall productivity. Despite these advantages, some users may encounter challenges during operation. Understanding these potential pitfalls is crucial for effective use.

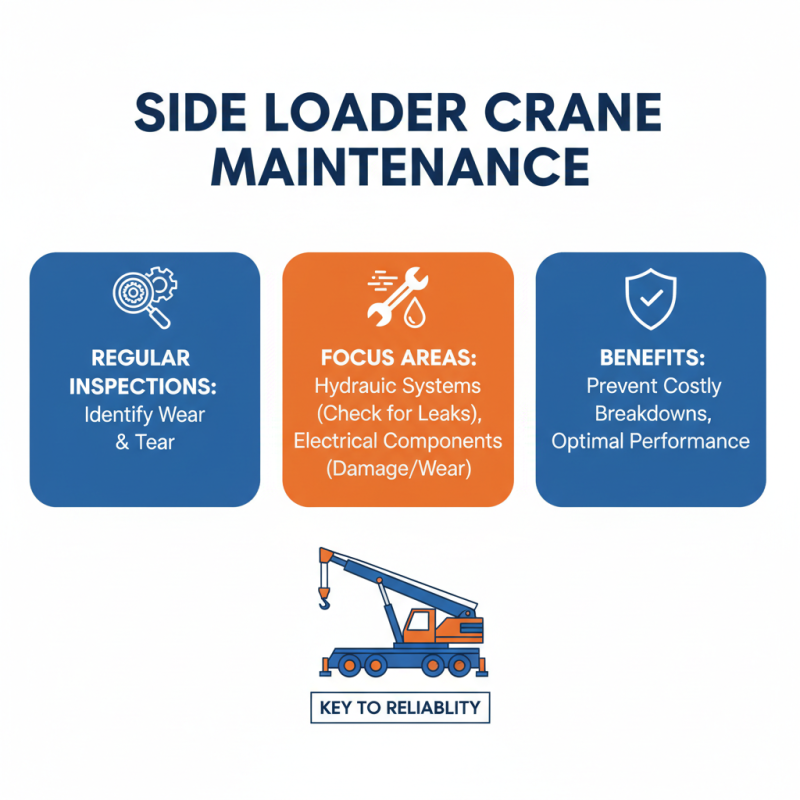

Maintenance and training are often overlooked areas. Operators must be well-informed about safety protocols. This ensures a smooth operation and extends the crane’s lifespan. Embracing these aspects can lead to better outcomes in any workplace utilizing a Side Loader Crane.

Side loader cranes are invaluable in various industrial settings. Their design allows for efficient loading and unloading of cargo. This is particularly important in tight spaces where traditional cranes struggle. The main features include the ability to handle long and bulky loads. They are often equipped with specialized attachments for improved efficiency.

When considering a side loader crane, think about its weight capacity. It's crucial for ensuring safe operations. Additionally, pay attention to the lift height. This impacts how much cargo can be moved effectively. Not all models perform equally in these aspects. Some may struggle under heavy loads, leading to potential issues.

**Tips:** Regular maintenance is essential for optimal performance. Check master cylinders and hydraulic hoses often. This can prevent sudden breakdowns. Also, train operators thoroughly. They should understand the limits of the crane. Overestimating capabilities can lead to accidents. Choose a model that fits your specific needs. Don't rush the decision. It's worth taking the time to evaluate options.

| Feature | Benefit | Use Case |

|---|---|---|

| Versatility | Can handle various load types | Used in construction and distribution |

| Compact Design | Ideal for limited space operations | Warehouse stacking and loading |

| Operability | Easy to operate with minimal training | Transportation and logistics |

| Increased Efficiency | Reduces loading and unloading times | Shipping and receiving docks |

| Safety Features | Minimizes accidents and injuries | Construction sites and busy warehouses |

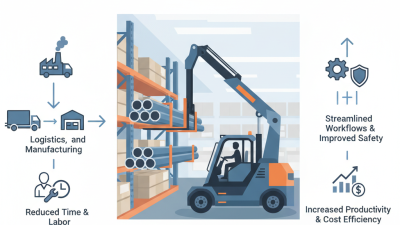

Side loader cranes are becoming essential in various industries. Their design allows for the efficient handling of long and heavy loads. This is especially beneficial in logistics and construction. These cranes are often used for transporting steel, timber, and pipes. Their ability to unload from the side makes them unique.

In warehousing, side loader cranes save space. They fit into tight areas where traditional forklifts may struggle. This efficiency can lead to increased productivity. Operators find that side loaders can be easy to maneuver. However, training is crucial; not all operators adapt quickly to their quirks.

Another advantage is the reduced risk of damage. Side loaders can pick up loads without excessive swinging. This reduces the chance of accidents. However, they require careful operation. Misjudgment can lead to mishaps. Companies should prioritize operator training and safety protocols.

Side loader cranes play a crucial role in material handling across various industries. They are particularly valuable in environments where space is limited. With a design that allows for lateral loading and unloading, these cranes excel in tight spaces such as warehouses and manufacturing facilities. According to industry data, approximately 40% of materials handled in warehouses require lateral handling solutions. This data highlights the importance of side loader cranes in optimizing workflow and improving efficiency.

Common applications for side loader cranes include steel handling, timber processing, and container transportation. In these sectors, side loaders can effectively manage bulky and cumbersome loads without requiring extensive maneuvering space. For example, the construction industry frequently uses these cranes for transporting heavy steel beams, where traditional forklifts might struggle. Reports indicate that using side loader cranes can reduce loading and unloading times by up to 30%, showcasing their efficiency.

However, these cranes are not without their challenges. Operators must undergo proper training to handle the unique risks presented by side loaders. Improper use can lead to accidents, especially in confined spaces. Awareness of operational limits is crucial. Continuous improvement in operator training and crane technology is necessary to maximize safety and efficiency in material handling operations.

Side loader cranes have gained popularity due to their unique features and benefits. Unlike traditional cranes, side loaders operate by picking up loads from the side rather than the top. This configuration is particularly effective in tight spaces. Additionally, they offer excellent stability and can maneuver easily in crowded environments.

When comparing side loader cranes to other types, one key difference is the loading approach. While tower cranes lift materials from above, side loaders excel at side access. This makes them ideal for industries like construction and shipping. However, they may not be as versatile in vertical lifting as some other cranes. Users need to consider their specific needs before making a choice.

Tips: Always assess your workspace. Ensure there is ample room for a side loader to operate safely. Remember to look at the lifting capacity of the crane too. It can determine how much you can move efficiently. Additionally, keeping an eye on maintenance is crucial. Neglect can lead to operational issues in the long run.

Maintaining side loader cranes is essential for ensuring optimal performance. Regular inspections help identify wear and tear. During these check-ups, operators should focus on hydraulic systems and electrical components. Inspect hydraulic hoses for leaks. Look for signs of damage or excessive wear. Keeping these parts in good shape can prevent costly breakdowns.

Another crucial aspect of maintenance is proper lubrication. Lubricate all moving parts regularly to minimize friction. This simple step can extend the lifespan of the crane significantly. Operators should also monitor the crane's load capacity. Overloading can lead to dangerous situations and equipment failure. Keeping track of lifting limits is vital for safety.

Operators must pay attention to the tires as well. Worn-out tires can lead to stability issues. Ensure that they are inflated to the recommended pressure. It's essential to keep tires in good condition. Finally, maintaining a clean working environment greatly contributes to crane performance. Keeping the area free of debris prevents accidents and promotes a smoother operation. Regular maintenance checks are vital, yet some areas often get overlooked. Taking the time to address these issues pays off in the long run.