Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

When it comes to selecting a slewing crane, industry experts often highlight the importance of making informed choices. John Smith, a leading authority in construction equipment, emphasizes, “A well-chosen slewing crane can transform your project’s efficiency.” This insight underscores the critical role of slewing cranes in modern construction.

Choosing the right slewing crane involves understanding specific project requirements. Factors such as load capacity, reach, and mobility are paramount. However, many overlook the significance of the crane’s stability and support. Making mistakes in these areas can lead to accidents and project delays.

Additionally, the market offers various options, making selection overwhelming. It’s vital to compare brands and models carefully. Not all slewing cranes are built equally, and certain features may be unnecessary. Reflecting on these considerations can lead to better decisions and safer operations on site. Ultimately, choosing the right slewing crane is essential for minimizing risks and maximizing productivity.

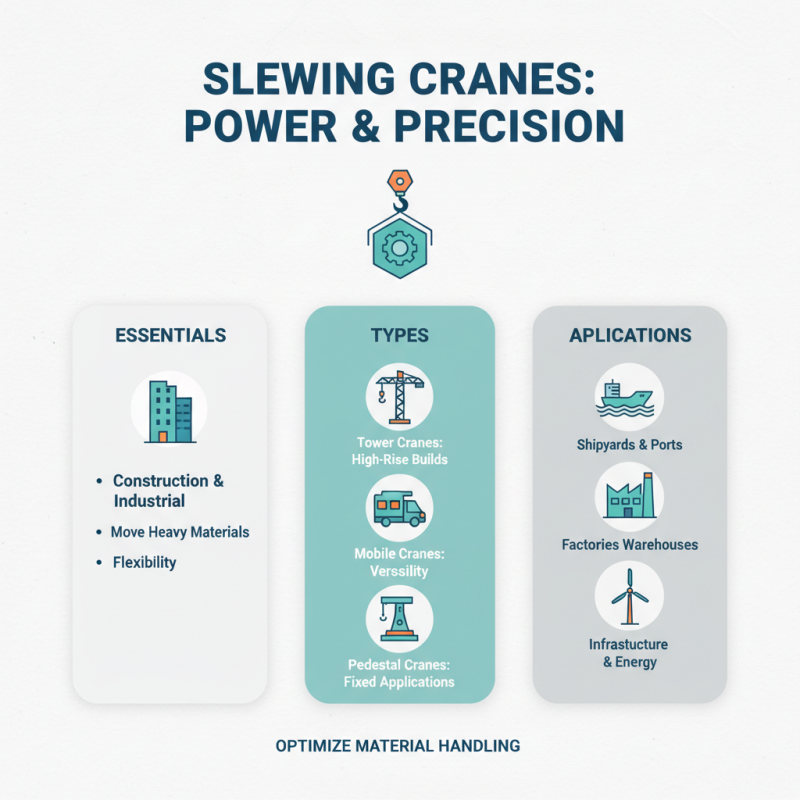

Slewing cranes are essential in construction and industrial applications. They provide flexibility in moving heavy materials. Different types of slewing cranes exist. Each type serves specific needs. Understanding their applications can make a significant difference.

Tower cranes are commonly used in tall building projects. They offer height and stability. Mobile cranes, on the other hand, provide mobility. They can easily relocate to different job sites. Floating cranes are used in marine applications. They handle heavy lifting over water, but logistics can be challenging.

Choosing the right type isn’t always straightforward. Consider the operational environment and the load capacity. Sometimes, users overlook space constraints. It’s crucial to assess how much room you have. Not every crane will fit comfortably on your site. Additionally, operator skill levels can vary. This factor can impact crane performance significantly.

Choosing the right slewing crane involves considering several key factors. Load capacity is essential. Understand the weight of items you frequently lift. This clarity helps avoid overloads. Swing radius matters too. Ensure the crane can maneuver in your work area without risking damage.

Next, think about lift height. Assess where you will operate the crane. Height requirements can affect your efficiency. Another factor is the crane’s versatility. Some models handle multiple tasks better than others. Identify what functions you need.

Don't overlook maintenance needs. Some cranes require more upkeep, which can increase costs. Cost is often a deciding factor. Aim for a balance between quality and budget. Renting might be an option, yet it has pros and cons. Reflect on your long-term needs. This approach can save resources in the long run.

When selecting a slewing crane, evaluating load capacity is crucial. Different industries have unique lifting demands. For example, construction sites often require cranes with a load capacity ranging from 10 to 100 tons. This wide range indicates varied project needs. A miscalculation here can lead to serious operational issues.

Reach is another essential factor to consider. The crane's boom length defines how far it can extend. Industry reports show that cranes with a reach of at least 30 meters are common for lifting on larger sites. Yet, not all crane operators recognize the importance of this measurement. Inadequate reach can limit project flexibility, especially in tight spaces.

Understanding your specific needs is vital. Many users overlook the importance of regular equipment assessments. Data suggests that up to 30% of cranes are underutilized. This underlines the need for choosing wisely. It’s not just about capacity; it’s about how well the crane fits within your operational framework.

When selecting a slewing crane, safety features should be the main focus. These features can save lives and prevent serious injuries. For example, overload protection is essential. It helps prevent the crane from lifting beyond its capacity. Without it, accidents can happen quickly and with devastating outcomes.

Another important aspect is emergency stop buttons. These allow operators to halt crane operations in critical situations. They should be easily accessible from various positions. Proper visibility and signage around the crane also enhance safety. In chaotic work environments, clear indicators reduce confusion and promote awareness.

Operators should also consider stability systems. Cranes can sway or tip if not properly supported. Outriggers can stabilize the unit, but they must be set up correctly. Many users underestimate the importance of proper setup, which can lead to tragic mistakes. Inadequate training on safety features also contributes to risks. Investing time in understanding these components can prevent future regrets.

| Feature | Importance | Recommended Safety Rating | Notes |

|---|---|---|---|

| Load Capacity | Prevents overloads that could cause tipping | Minimum 125% of operating capacity | Check manufacturer's specifications |

| Anti-Collision Features | Prevents accidents with other structures or equipment | Must have integrated sensors | Increase workplace safety |

| Emergency Stop System | Quickly halts operation in emergencies | Instant activation capability | Easily accessible by operators |

| Operator Training | Ensures proper handling and awareness of risks | Certification recommended | Regular refresher courses advised |

| Periodic Maintenance | Reduces the risk of malfunction | Follow manufacturer guidelines | Document all maintenance activities |

When selecting a slewing crane, maintenance and support are crucial factors. Regular upkeep can significantly affect its lifespan. Many operators overlook this aspect, focusing only on initial costs. A neglected crane can lead to severe long-term expenses. It's vital to choose one that comes with accessible support and strong service agreements.

Consider the availability of spare parts. Delays can cause operational downtime. Ensure your supplier has a reliable stock of parts. Training is another key element. Operators must understand proper handling to prevent misuse. A lack of knowledge can lead to accidents and increased wear. This is often a neglected area, yet it should be a priority.

Long-term support should include regular inspections. These help identify issues before they escalate. Investing in maintenance may seem costly upfront but is essential for safety and efficiency. Reflect on your operational needs. A well-maintained slewing crane optimizes productivity and reduces risks. Remember, cutting corners today can lead to high expenses tomorrow.