Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

In the realm of heavy lifting equipment, the choice of machinery can significantly impact project efficiency and safety. Telescoping cranes have emerged as a preferred solution due to their versatility and ability to handle various lifting conditions. According to industry reports, the global crane market is projected to reach approximately $50 billion by 2025, with telescoping cranes increasingly being recognized for their space-saving design and ease of transportation. Their extendable boom allows for higher outreach capabilities, making them suitable for construction, shipyard, and industrial applications where traditional cranes may fall short.

Furthermore, with the rising trend of urbanization and infrastructure development, the demand for efficient lifting solutions continues to grow. A study highlighted in the Journal of Heavy Engineering indicates that the use of telescoping cranes can reduce project timelines by up to 20%, thanks to their quick setup and operational flexibility. This combination of innovative design and operational efficiency positions telescoping cranes as a leading choice for businesses seeking reliable and effective heavy lifting solutions. As companies strive to enhance productivity and safety, integrating telescoping cranes into their operations becomes not just advantageous, but essential for staying competitive in an increasingly demanding industry landscape.

Telescoping cranes are specialized lifting machines designed with a series of nested sections that extend or retract to adjust their height and reach. The fundamental mechanism of a telescoping crane relies on hydraulic systems, which allow for smooth extension and retraction of the crane's boom. When a job requires lifting heavy loads to significant heights, these cranes provide an efficient solution due to their ability to reach over obstacles and into confined spaces, where traditional cranes may struggle.

The operation of a telescoping crane involves a combination of hydraulic cylinders, pulleys, and winches that work in tandem. As hydraulic fluid is pumped into the cylinders, the crane’s boom extends outward, providing an elevated platform for lifting. The design ensures stability while maximizing load capacity, as the weight is distributed across multiple sections of the boom. Furthermore, the cranes can be fitted with various attachments to enhance versatility, whether for construction, material handling, or industrial applications, making them essential tools in heavy lifting scenarios.

This chart illustrates key attributes of telescoping cranes that make them suitable for heavy lifting operations. The lifting capacity, range, setup time, and cost are essential factors to consider when choosing a lifting solution.

Telescoping cranes are becoming increasingly popular in heavy lifting applications due to their unique design and operational advantages. One of the primary benefits of these cranes is their ability to extend and retract their boom, allowing for versatile maneuverability in confined spaces. This feature is particularly advantageous in urban environments or construction sites where space is limited, as it enables operators to position the crane optimally without the need for extensive repositioning.

Moreover, telescoping cranes often offer enhanced lifting capacities compared to traditional cranes. Their structural design allows for a more substantial load-bearing capability, making them ideal for lifting heavy materials such as steel beams and concrete blocks. The ease of extending the boom means that operators can access high or distant loads without compromising safety, improving both efficiency and productivity on the job site. Additionally, many telescoping cranes include advanced stabilization systems, which contribute to safer lifting operations and reduce the risk of accidents during heavy lifting tasks.

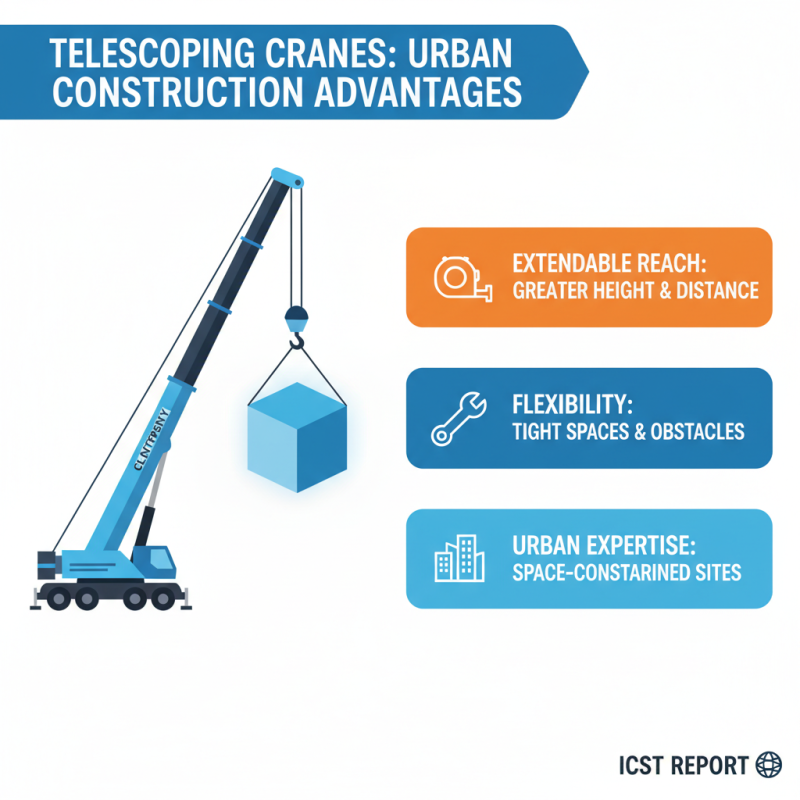

When it comes to heavy lifting, selecting the right crane is crucial to ensuring efficiency and safety on job sites. Telescoping cranes offer distinct advantages over other types of cranes, such as fixed or lattice boom cranes. According to a report by the International Cranes and Specialized Transport (ICST), telescoping cranes can extend their boom length significantly, often reaching heights and distances that are unattainable by their non-telescopic counterparts. This ability to adjust the boom length allows for greater flexibility when navigating tight spaces, making telescoping cranes ideal for urban construction projects where space is at a premium.

Moreover, telescoping cranes are often easier to transport and set up compared to other crane types. The rapid deployment feature allows operators to quickly get to work, reducing downtime and increasing productivity. Data from the Specialized Carriers & Rigging Association (SC&RA) indicates that projects using telescoping cranes typically report up to a 20% reduction in operational time due to their easier setup and maneuverability. This efficiency not only saves time but also cuts down on labor costs, making telescoping cranes a cost-effective choice in the long run. The modern engineering behind telescoping mechanisms combines safety with functionality, solidifying their place in the heavy lifting landscape.

Telescoping cranes are increasingly favored in industrial operations due to their remarkable safety features that enhance the well-being of workers while performing heavy lifting tasks. One of the primary safety attributes of these cranes is their ability to extend and retract smoothly, providing greater reach without compromising stability. This design minimizes the risk of tipping, a common concern in heavy lifting scenarios. Moreover, the integrated hydraulic systems ensure precise control over the crane’s movements, allowing operators to maneuver loads with exactness and care.

Another significant safety feature is the inclusion of advanced monitoring systems that provide real-time feedback on the crane's operational status. These systems can alert operators to potential hazards, such as exceeding weight limits or unstable load positions. Additionally, telescoping cranes are usually equipped with automatic shut-off mechanisms that activate in case of detected malfunctions, further safeguarding personnel and equipment. Enhanced visibility from the operator’s cabin, often combined with modern camera systems, also contributes to safer lifting by allowing operators to see the load and work area clearly, reducing the likelihood of accidents during operations.

| Feature | Description | Benefits |

|---|---|---|

| Stability Control System | Automatically adjusts the crane's position to maintain stability during operations. | Reduces the risk of tipping and enhances safety. |

| Load Moment Device | Monitors the load weight and warns if it exceeds capacity. | Prevents overloading, ensuring safe operation. |

| Operator Safety Cab | Enclosed cab with protective features for the operator. | Enhances operator safety and comfort during lifting tasks. |

| Anti-collision System | Detects obstacles in the crane's path to prevent accidents. | Minimizes the risk of collisions, protecting personnel and equipment. |

| Remote Control Operation | Allows operators to control the crane from a safe distance. | Reduces exposure to hazards and enhances overall safety. |

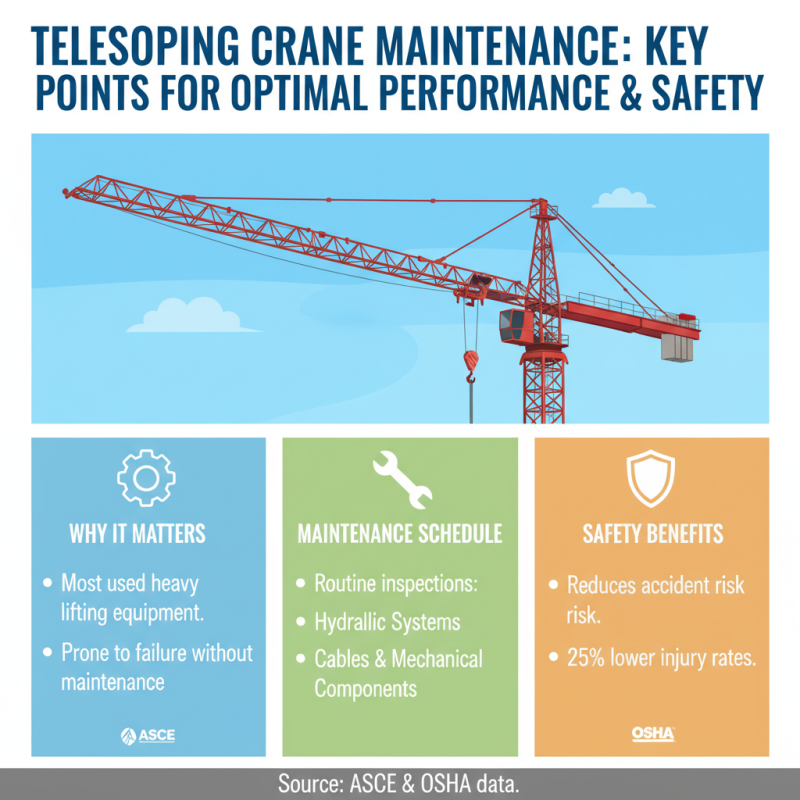

To ensure optimal performance of telescoping cranes, regular maintenance is crucial. The American Society of Civil Engineers (ASCE) reports that cranes are among the most frequently used types of heavy lifting equipment, yet they are also among the most prone to operational failures if not well-maintained. Maintenance schedules should include routine inspections of hydraulic systems, cables, and mechanical components to identify wear and tear before they lead to breakdowns. According to the Occupational Safety and Health Administration (OSHA), engaging in preventive maintenance can significantly reduce the risk of accidents, with well-maintained equipment leading to a 25% decrease in injury rates on job sites.

Another important aspect of telescoping crane maintenance is ensuring proper lubrication of moving parts. The National Crane Safety Association emphasizes that inadequate lubrication is a common factor in many crane malfunctions. By following manufacturer guidelines for lubrication frequency and using the appropriate lubricants, operators can enhance the lifespan of critical components, which can positively impact overall crane uptime. Furthermore, keeping detailed logs of maintenance activities can help track the performance and identify patterns that inform better operational decisions, ultimately leading to improved efficiency and cost savings for any lifting operation.