Leave Your Message

-

Phone

-

E-mail

-

WhatsApp

In the construction and logistics industry, Towing Cranes play a vital role. These powerful machines are essential for moving heavy loads safely. As we look ahead to 2026, various models are emerging, each with unique features.

Towing Cranes are becoming increasingly advanced. New technology enhances efficiency and safety. However, not all models meet the same standards. Some companies struggle to choose the right crane for their needs. Details matter when selecting a towing crane. Consider the load capacity, reach, and maneuverability. Each feature impacts performance in real-world applications.

It's important to reflect on these choices. Investing in the wrong towing crane can lead to costly mistakes. Each model has strengths and weaknesses, and understanding them is crucial. As we delve into the top models of 2026, we will explore their key features and how they address specific job requirements.

The year 2026 promises exciting developments in towing crane models. Industry reports highlight a shift towards more efficient and versatile designs. These new cranes are built for various applications, boosting productivity and safety.

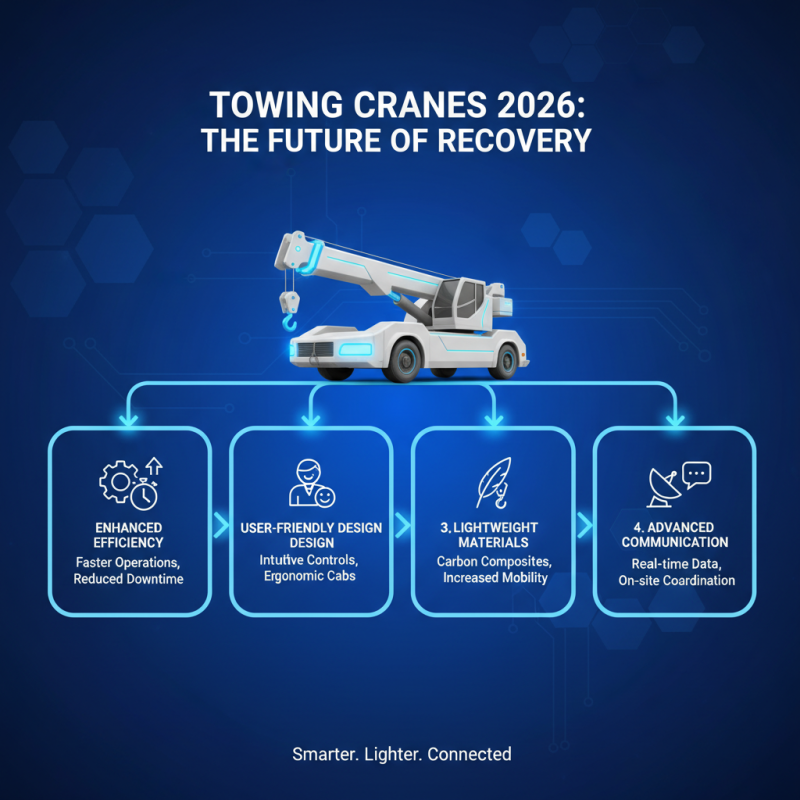

Key features to look for include advanced hydraulic systems. Such systems improve lifting capabilities while reducing energy consumption. Some models now offer intuitive control systems. These controls make it easier for operators to manage loads. Enhanced stability features are also critical, especially for heavy lifting. This year, safety ratings are more stringent, emphasizing the importance of reliability.

Tips: Balance between power and ease of use is crucial. Operators should receive training on new technologies. Regular maintenance checks will help maximize crane lifespan and performance. Remember, innovation in crane technology can lead to unexpected challenges. Staying informed about new features can help avoid operational issues.

In 2026, towing cranes have evolved significantly. They are now more efficient and user-friendly. Many models focus on lightweight materials, enhancing mobility. Operators appreciate cranes with advanced communication systems. These features improve coordination on-site, reducing errors.

Safety remains a top priority in design. Innovative models include overload protection systems. This feature alerts operators to potential dangers. Compact designs also make towing easier in tight spaces. However, some users find these new systems complicated. A steeper learning curve can deter less experienced operators.

Many cranes now offer automation features. Automated controls help in precision lifting. This can save time and improve productivity. Yet, there can be glitches in high-demand scenarios. Maintenance is crucial, but often overlooked. Regular checks can prevent costly downtime. Not all operators heed these warnings. Balancing high-tech features with user comfort is a work in progress.

When assessing the top towing crane models for 2026, load capacity and lifting height are crucial. Most cranes on the market offer a load capacity ranging from 10 to 200 tons. However, the highest-performing models can support over 300 tons. These statistics underline the shift toward cranes that can handle heavier loads while maintaining efficiency.

Lifting height also varies significantly among models. Many cranes are designed to reach heights of up to 50 meters. A few exceptional models can achieve heights exceeding 70 meters. According to industry reports, cranes that combine a high load capacity with extended lifting height are becoming increasingly popular. Operators often face challenges when selecting models that perfectly balance these two metrics.

Users frequently express concerns about the stability of cranes with high capacities. There have been incidents of cranes failing to lift loads safely. This raises questions about engineering practices in crane production. Understanding the metrics will help operators make informed decisions. In a competitive landscape, balancing performance with reliability is key.

In 2026, the towing crane industry is witnessing a revolution. Automation is at the forefront, driving efficiency and safety. Over 40% of new crane models now feature automated controls. These systems allow for precise movements while reducing human error.

Innovative technologies, such as real-time data analytics, enhance crane performance. For instance, cranes equipped with advanced sensors can monitor load stress and detect potential failures. Reports indicate that these features can lower maintenance costs by up to 30%. However, implementing these technologies requires a skilled workforce, which can be a challenge.

Tips: Invest in training programs for operators to fully utilize automation. Regularly update your fleet to include cranes with the latest tech. Be mindful of the balance between efficiency and oversight; automation should complement, not replace, human input.

This chart represents the lifting capacity (in tons) and efficiency rating (on a scale of 1 to 10) of various popular towing crane models in 2026. The data highlights advancements in automation and efficiency within the industry.

In 2026, safety standards for towing cranes will undergo significant evolution. Regulations are becoming stricter as safety concerns grow. Manufacturers need to design models that exceed minimum requirements. Key features must include advanced stability systems and improved load monitoring. These innovations are crucial for preventing accidents. Incorporating real-time data analytics can enhance performance and safety.

The regulation landscape impacts towing crane models deeply. Compliance with updated safety norms is essential. Features like automatic shut-off mechanisms will be vital. These systems prevent crane failures during operation. Operators must receive thorough training. Yet, not all operators are currently prepared for these changes. Some may resist new technologies, fearing complexity. Manufacturers must address this gap through enhanced user-friendly designs.

Moreover, regular inspections will likely become mandatory. This could increase operational costs for operators. The challenge lies in balancing safety and functionality. While regulations aim to protect, they might also hinder efficiency. Emphasizing communication between manufacturers and users is necessary. Feedback can drive innovations that enhance both safety and usability. Embracing change will lead to better practices in the towing crane industry.