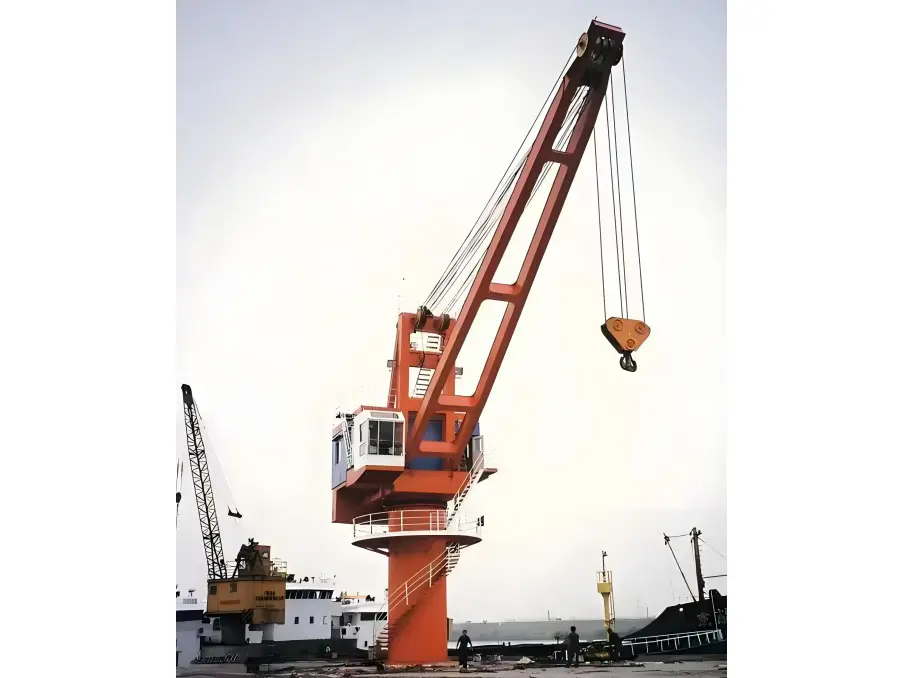

Container and Cargo Handling shipboard Crane Fixed Stiff Boom Crane with steel wire luffing

Application

1.Shipboard Operations: Ideal for ship decks, these cranes are used to load and unload containers and cargo. Their high hoisting capacity and long working radius enable efficient handling of large - scale shipments.

2.Dock and Harbor Use: They can also be fixed in docks and harbors, where they play a crucial role in the logistics chain, ensuring smooth transfer of goods between ships and land.

Model Ranges

Available with lifting moments from 120 to 36,000 kNm, these cranes can be customized according to customer requirements. Whether it's a smaller operation requiring a lower lifting moment or a large - scale industrial task needing a higher capacity, there's a suitable model.

| Product range | ||||

| Crane type | MAX 150 | MAX 250 | MAX 500 | MAX 800 E |

| Max. capacity | 120-180 t | 250 t | 400-500 t | 800-1000 t |

| Typical outreach | 33 m | 33/36 m | 33/36 m | 39 m |

| Auxiliary Hoist | 45 t | 45 t | 60 t | 60 t, 10 t sling |

Features

1.Powerful Performance: The high hoisting capacity and long working radius make it a capable machine for heavy - duty tasks.

2.Durability: Long - life surface treatment, stainless - steel pipes, and special corrosion treatment ensure the crane can withstand harsh marine environments, reducing maintenance needs.

3.Safety Features: Anti - collision system, overload protection, and explosive - protection design, enhance safety during operation.

4.Flexible Operation: Continuous slewing, low/high - temperature operation capabilities, and options for remote control or operator's cabin provide flexibility in different working conditions.

5.Customization: The crane can be delivered with a broad range of certifications and numerous optional features, allowing it to meet specific industry regulations and user needs.

Certificates

1. Manufacturing Standards: The product is designed and manufactured in strict accordance with the latest effective specifications of the classification society at the time of contract signing to ensure that the product quality meets industry standards.

2. Classification Societies: BV, CCS, ABS, KR, LR , et.

3. Testing and Certification: Before leaving the factory, the equipment needs to undergo strict tests, including performance tests (lifting, luffing, and slewing movements with rated and overload loads), emergency stop confirmation, manual brake release tests, limit switch confirmation (under no - load conditions), and insulation resistance measurement. The test records of each item will be submitted to users to ensure reliable product performance.

4.Industry Certifications: Quality certificates and factory test reports are provided to provide strong evidence for product quality and allow users to use the product with confidence.Safety Certifications: CE (European Union), ISO 9001(International Organization for Standardization)

3. We have launched cross-border collaborations with many innovative well-known enterprises, jointly exploring new directions for the future development of the industry.

description2