Containers and Cargo Handling Stiff Boom Marine Crane Electrical Hydraulic with Cylinders Luffing

Application

MAXTECH marine cranes are widely applied in various maritime scenarios.

1.At ports, it can efficiently handle the loading and unloading of both containers and bulk cargo, facilitating smooth port operations.

2.On ships, it can easily lift heavy machinery and large shipments. Thanks to its rational design, in dock areas, it enables the convenient transfer of goods between vessels and the shore.

3.It is highly popular among platform service vessels in the Middle East and can be used for offshore operations such as equipment installation and material transportation. Additionally, the crane can be customized to adapt to extreme temperature environments, ensuring uninterrupted operation.

Model Ranges

Maxtech marine cranes offer great flexibility in lifting capacity and working radius.

1.The lifting capacity ranges from 1 ton to 100 tons, allowing users to select according to the ship size and cargo type. Smaller ships can choose models with lower lifting capacity, while larger ships handling heavy loads can opt for those with higher lifting capacity.

2.The working radius can be customized between 5 meters and 50 meters. Shorter radii are suitable for confined areas, while larger radii are more advantageous in vast ports and offshore platforms.

| Crane Type | Outreach (m) | Lifting Capacity (t) | Lifting Moment (kNm) | Total Moment (kNm) | Pedestal Diameter (mm) | Dead Weight (t) |

| MAX 200 | 6-16 | 3.5-0.9 | 144-210 | 270 | 885 | 2.7-3.2 |

| MAX 400 | 6-16 | 5.6-1.7 | 288-336 | 424 | 885 | 3.2-3.7 |

| MAX 600 | 6-20 | 10-2.3 | 460-600 | 737 | 1095 | 4.4-5.5 |

| MAX 900 | 6-20 | 14.2-3.2 | 640-852 | 1039 | 1325 | 5.9-7.0 |

| MAX 1200 | 6-24 | 19-3.5 | 840-1140 | 1409 | 1490 | 7.8-10.2 |

| MAX 1500 | 7-24 | 20.3-4.6 | 1104-1421 | 1765 | 1490 | 9.2-11.3 |

| MAX 1800 | 7-24 | 25.6-5.4 | 1296-1792 | 2202 | 1770 | 11.4-14.1 |

| MAX 3000 | 21 | 12.5 | 2625 | 3750 | 1775 | 24.8 |

Just let us know your requirements, and our engineers will design a bespoke solution for you.

Features

1.Sturdy Structure: Based on a pedestal slewing design with cylinders, it features a simple yet efficient structure, ensuring stability and low maintenance. The use of high-quality components achieves a balance between performance and durability.

2.Excellent Rust Prevention: Stainless steel materials are widely used in key components, and special anti-corrosion treatments are applied, significantly enhancing its resistance to the marine environment and extending its service life.

3.Advanced Hydraulic System: The integrated electro-hydraulic system, equipped with stainless steel pipes, operates smoothly and prevents leakage.

4.Flexible Operation: It has the function of continuous slewing and can operate in different temperature environments.

5.Multiple Safety Guarantees: Equipped with an anti-collision system, overload protection device, and offering options for remote control or cabin control, it ensures operational safety in all aspects.

6.Rich Extended Functions: It can be equipped with external power units, spray metalizing, relevant certifications, explosion-proof designs, tugger winches, and more.

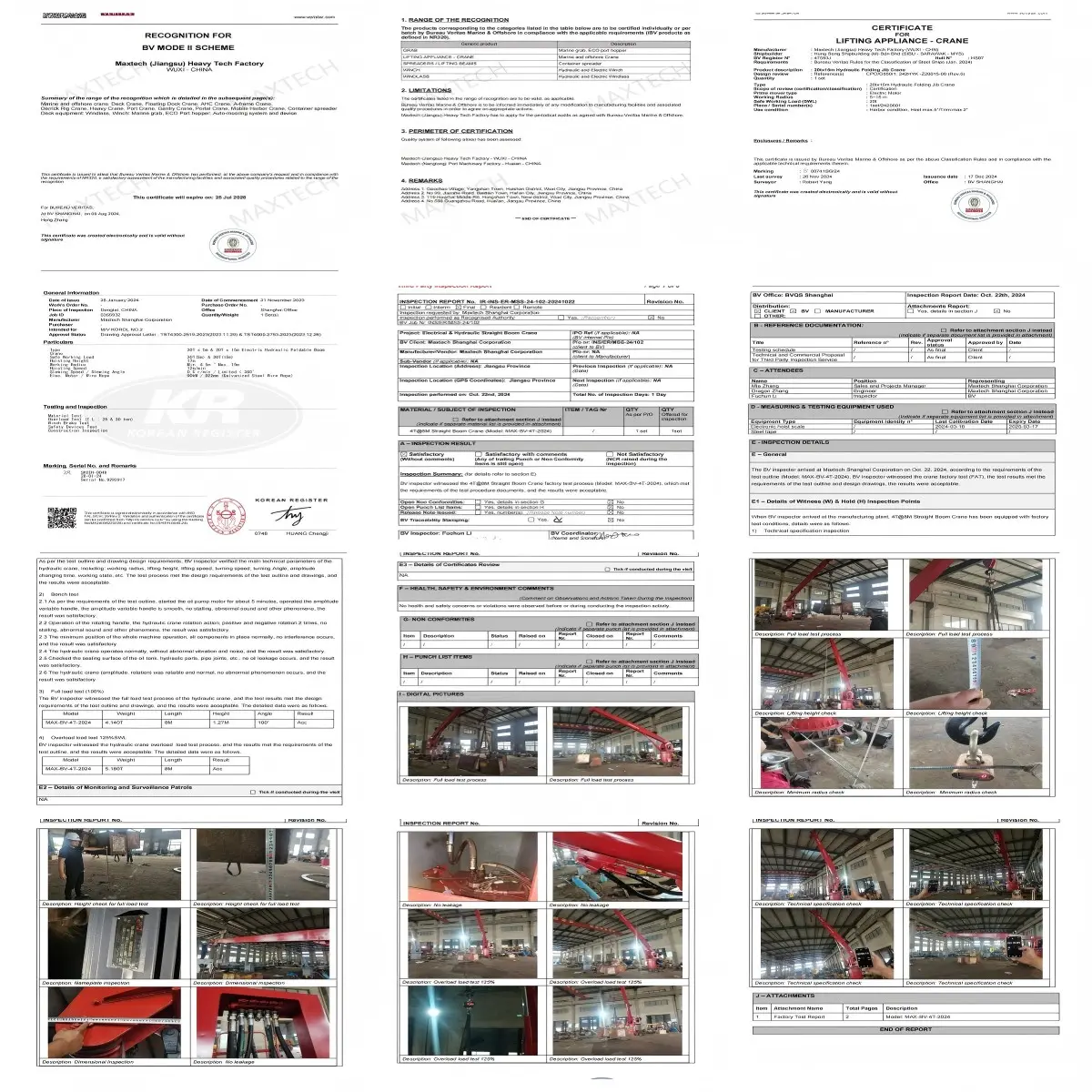

Certificates

1. The product is designed and manufactured in strict accordance with the latest effective specifications of the classification society at the time of contract signing to ensure that the product quality meets industry standards.

3. Industry Certifications

We provide comprehensive after-sales services to ensure that your crane is always in optimal operating condition. If you have any requirements, please send us an inquiry with your working requirements, and we will provide you with a free quotation.

description2